onthewater102

Well-known member

Ok, here we go - this is why I signed up here so that I could pick the brains of so many experienced folks...I'm decking a 1436LT - plan is to put a livewell inside of the middle seat (replacing the foam), framing the decking with aluminum and topping everything using FRP backed by expanding urethane foam. In the end the deck will be coated in Tuff Coat rubberized marine coating.

The final product (sans accessories alla trolling motor, battery, fuel, motor etc.) should weigh in under 230lbs - this is important as there is only carry-in access to the river behind my house where I will keep this tied up. I'm looking for suggestions on the design/layout or issues that other people encountered in their builds or after the fact that caused them to revisit something...

The volume of foam behind the decking is almost double that removed from the center seat - though I plan on filling all non-storage areas in the bow section with 2# expanding urethane (overkill is underrated.) Ok, so the plans at the moment look like this:

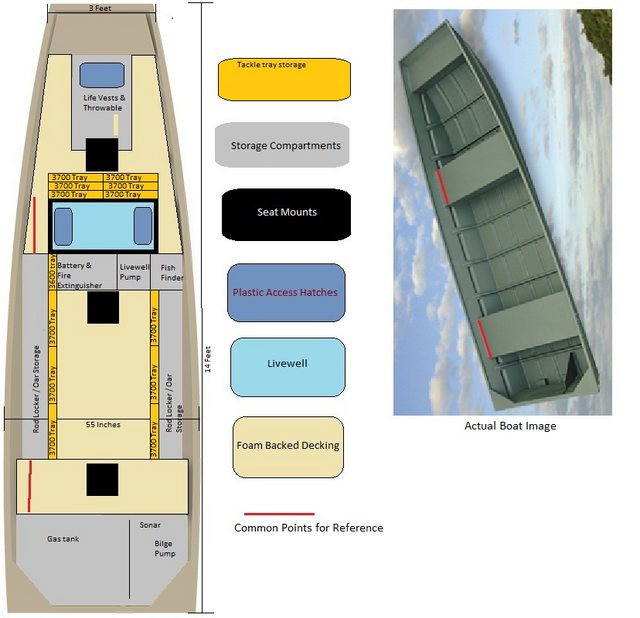

Finished product's decking layout will loosely resemble this - major differences being the side rod-lockers rather than shelves and the layout of the hatches / livewell & hardpoints for seats. I will use a hole-saw to cut through the middle and rear bench seats and install PVC tubes extending up under the bow flooring and through the rear bench to allow for storage of 2, possibly 3 clearances permitting, 7' rods on each side of the boat. I live in a remote area, so being able to lock the rods in the boat and not have to lug everything up and down the bank would be nice.

Also - my flooring between the aft and middle bench seats will be anchored flush to the top of the structural ribs - all other decking surfaces will be roughly 1/2" higher than the plane of the middle and rear bench seats - with a step up to the bow bench which will be topped with the trolling motor mount, anchor mate (mechanical) and receptacle for the 12" pole-mounted bow-light (for visibility clearance above the trolling motor when stowed.)

I apologize for not referencing this builder and giving them credit - I saved the image during my research and didn't save the source.

The final product (sans accessories alla trolling motor, battery, fuel, motor etc.) should weigh in under 230lbs - this is important as there is only carry-in access to the river behind my house where I will keep this tied up. I'm looking for suggestions on the design/layout or issues that other people encountered in their builds or after the fact that caused them to revisit something...

The volume of foam behind the decking is almost double that removed from the center seat - though I plan on filling all non-storage areas in the bow section with 2# expanding urethane (overkill is underrated.) Ok, so the plans at the moment look like this:

Finished product's decking layout will loosely resemble this - major differences being the side rod-lockers rather than shelves and the layout of the hatches / livewell & hardpoints for seats. I will use a hole-saw to cut through the middle and rear bench seats and install PVC tubes extending up under the bow flooring and through the rear bench to allow for storage of 2, possibly 3 clearances permitting, 7' rods on each side of the boat. I live in a remote area, so being able to lock the rods in the boat and not have to lug everything up and down the bank would be nice.

Also - my flooring between the aft and middle bench seats will be anchored flush to the top of the structural ribs - all other decking surfaces will be roughly 1/2" higher than the plane of the middle and rear bench seats - with a step up to the bow bench which will be topped with the trolling motor mount, anchor mate (mechanical) and receptacle for the 12" pole-mounted bow-light (for visibility clearance above the trolling motor when stowed.)

I apologize for not referencing this builder and giving them credit - I saved the image during my research and didn't save the source.