FloridaGrown

Member

Been digging around for a while and decided to join up. First, great site, tons of info , Thank you. OK, so i picked up an Alumacraft 1436 and knew that the boat was going to get a floor because my i do not want my day or I to trip on ribs, dad has diabetes and his feet aren't so good.

Second, I knew i wanted a built in live/baitwell so no having to hang/pull up a baitwell.. dad is getting older and i wanted us both to have the luxury of just opening a lid.

after getting the boat home i began by cutting the middle bench open for the well..

along my way while cutting i decided since the boat will be a longtail, that it would probably be wise to "split" the rear bench.The rear bench still needs corners shaped once i go buy some aluminum and feel up to making them then welding them back shut.I'm leaving the foam in the rears as i have taken a large amount out from the rear split and the middle well areas.

Installed an at-500 aerator and plumbing

i have two overflows...one on each side of the boat so that regardless of weight distribution or if standing on one side the well cannot flood.

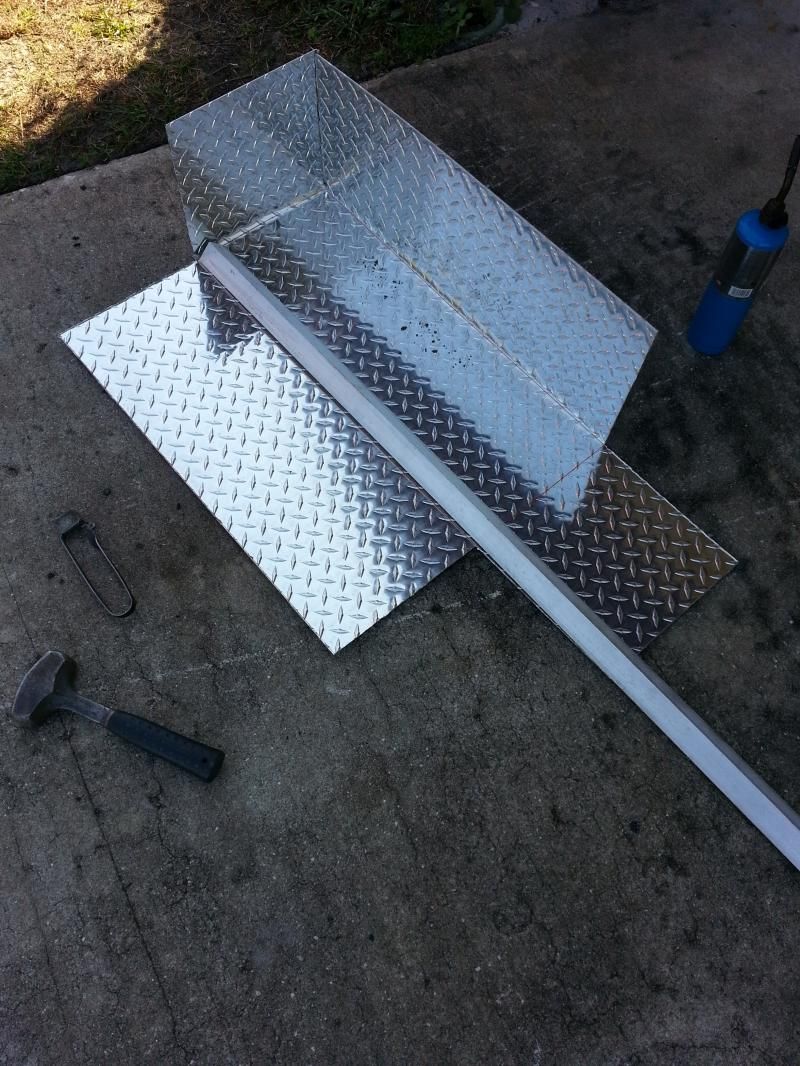

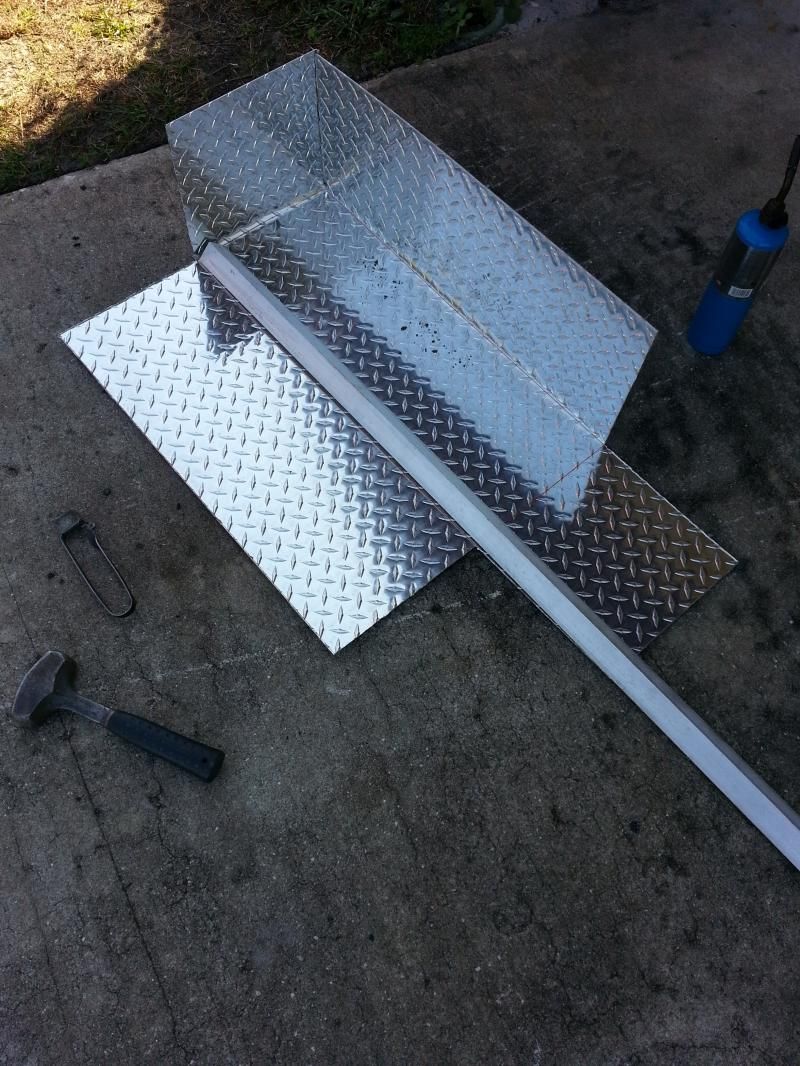

next i began on the well... don't laugh, i do not have a brake and since i have taken a %60 pay cut , i'm a poor white guy nowadays..i ended up using map gas (the propane didnt seem to get hot enough), a 3lb. sledge and you'll recognize the aluminum in the next few pics...

well rough fit in... corners need welded up, and in this pic no plumbing yet. The divider is for bait, it will just slide in via guide tab guides i am welding up.i also now have two underwater leds in the well that will run on a momentary switch that when the lid opens they will light the well up on both sides.

hull plumbing(one side) for the well and pictured is one of 4 LED shrimping lights 1650lumens @ 16W @12v. i don't think the boat will be stable enough to gig from but i'll sure be finding out once on water.

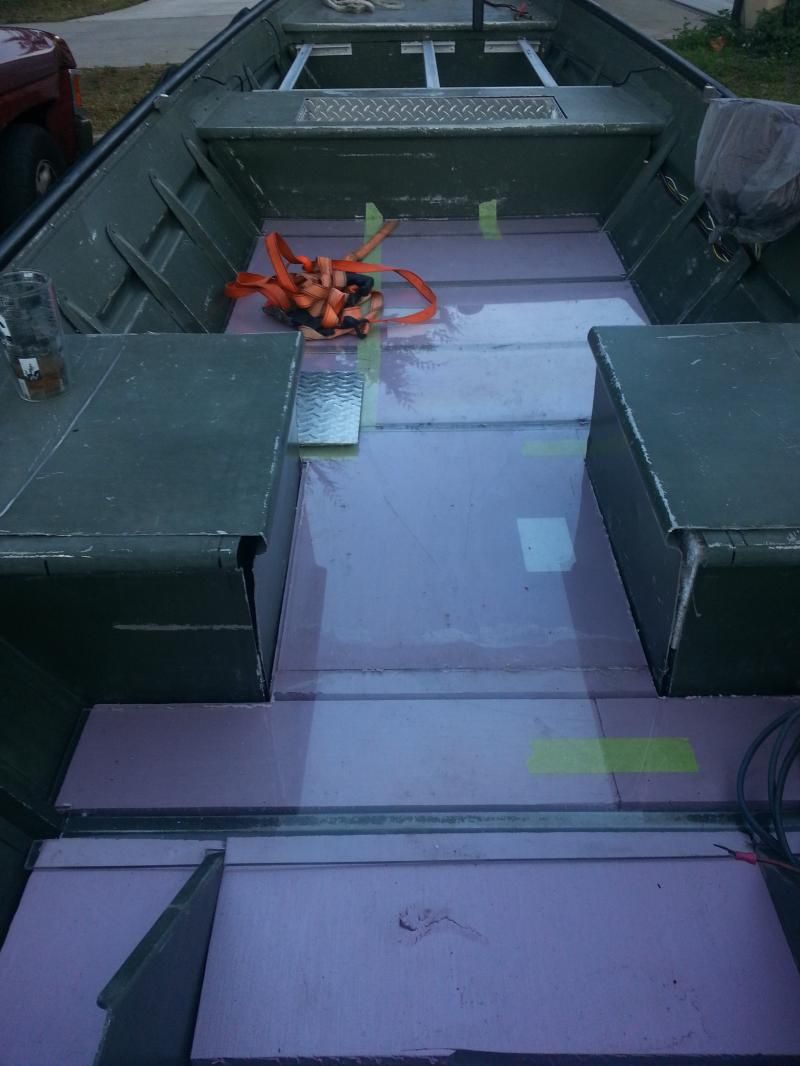

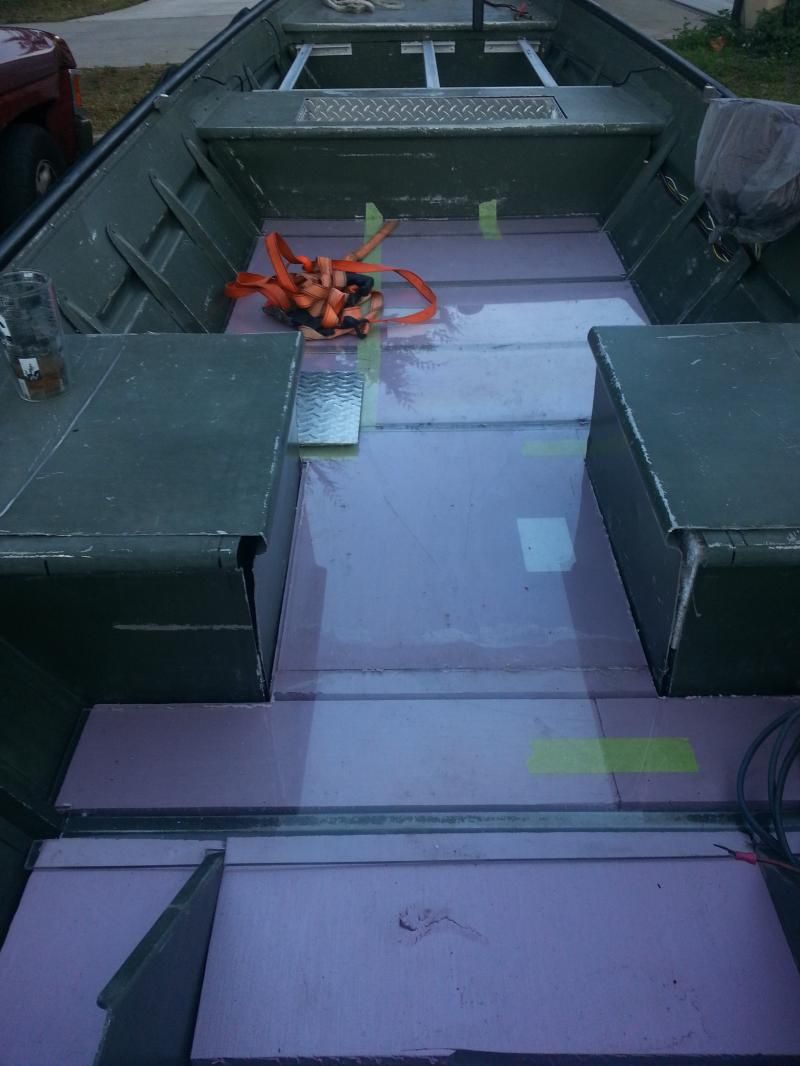

next up was back to working on flooring. first was figuring out what was out there i could use AND afford... after a lot of looking i ended up with some closed cell owens corning insulation.. and i scored some lexan from helping a friend move a few things from one storage unit into another one. for now it is just cut and laid on the floor. i plan on using some SBT blacktip turf as final flooring. once the turf is on the lexan then i will screw the flooring down. I figured to go turf for several reasons..

It floats, not much but i think ANY additional flotation i can add back in anywhere will help me with getting back where i need to with flotation. and turf is kinda spongy, im sure dad and i both will appreciate a comfy flooring..

continued ......

Second, I knew i wanted a built in live/baitwell so no having to hang/pull up a baitwell.. dad is getting older and i wanted us both to have the luxury of just opening a lid.

after getting the boat home i began by cutting the middle bench open for the well..

along my way while cutting i decided since the boat will be a longtail, that it would probably be wise to "split" the rear bench.The rear bench still needs corners shaped once i go buy some aluminum and feel up to making them then welding them back shut.I'm leaving the foam in the rears as i have taken a large amount out from the rear split and the middle well areas.

Installed an at-500 aerator and plumbing

i have two overflows...one on each side of the boat so that regardless of weight distribution or if standing on one side the well cannot flood.

next i began on the well... don't laugh, i do not have a brake and since i have taken a %60 pay cut , i'm a poor white guy nowadays..i ended up using map gas (the propane didnt seem to get hot enough), a 3lb. sledge and you'll recognize the aluminum in the next few pics...

well rough fit in... corners need welded up, and in this pic no plumbing yet. The divider is for bait, it will just slide in via guide tab guides i am welding up.i also now have two underwater leds in the well that will run on a momentary switch that when the lid opens they will light the well up on both sides.

hull plumbing(one side) for the well and pictured is one of 4 LED shrimping lights 1650lumens @ 16W @12v. i don't think the boat will be stable enough to gig from but i'll sure be finding out once on water.

next up was back to working on flooring. first was figuring out what was out there i could use AND afford... after a lot of looking i ended up with some closed cell owens corning insulation.. and i scored some lexan from helping a friend move a few things from one storage unit into another one. for now it is just cut and laid on the floor. i plan on using some SBT blacktip turf as final flooring. once the turf is on the lexan then i will screw the flooring down. I figured to go turf for several reasons..

It floats, not much but i think ANY additional flotation i can add back in anywhere will help me with getting back where i need to with flotation. and turf is kinda spongy, im sure dad and i both will appreciate a comfy flooring..

continued ......