summers

Well-known member

I am new to the site and boating but not to hard work and dedication. I bought my first boat this August in 2010 A simple 14' with a Mercury 25hp electric start. The boat is an 1986 Delta, I have not been able to find to much out about the manufacture other then where it was manufactured but time will only tell. Well the first thing was the trailer needed a little bit of work and I had a place to store the boat for a short while, so I got started on the trailer. The normal trailer makeover sanded, painted, new wires and light, bearings, and tires and wheels. I also replaced the safety chains and boat winch from a cable to a 2" strap. Here are a few pictures of my progress.

A simple before shot this was what the boat looked like after i cleaned it out and got it down to basics.

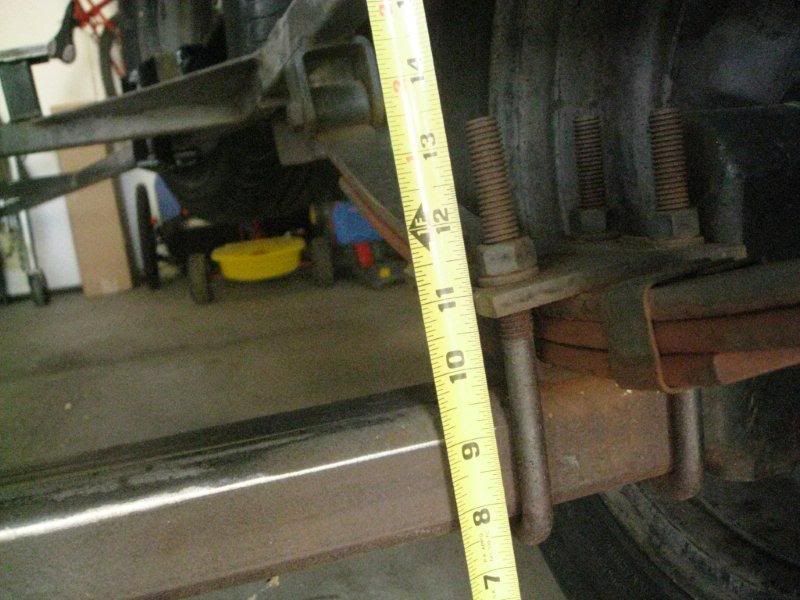

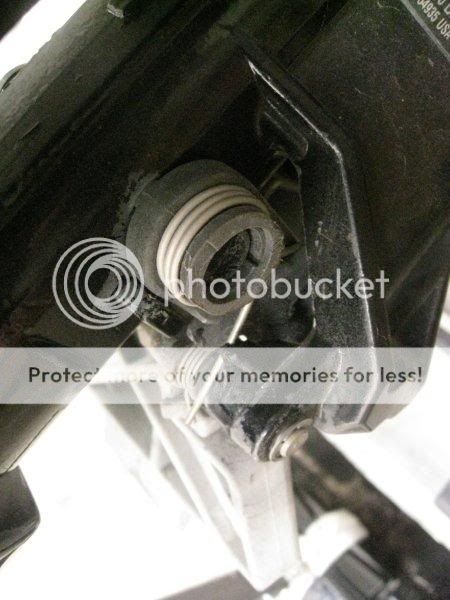

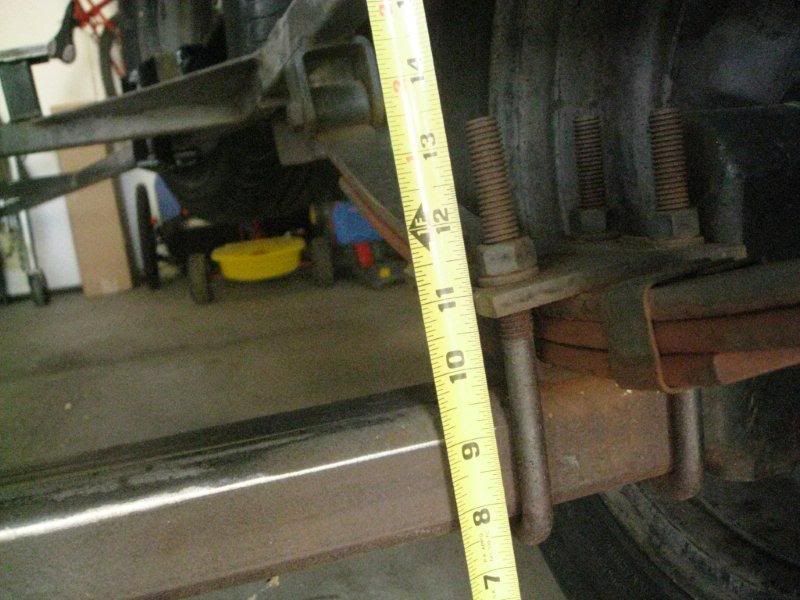

I did a spring under conversion on the trailer to help get the boat a little lower to make it a simple one man launch

before

A simple before shot this was what the boat looked like after i cleaned it out and got it down to basics.

I did a spring under conversion on the trailer to help get the boat a little lower to make it a simple one man launch

before