cajuncook1

Well-known member

- Joined

- Mar 24, 2010

- Messages

- 437

- Reaction score

- 1

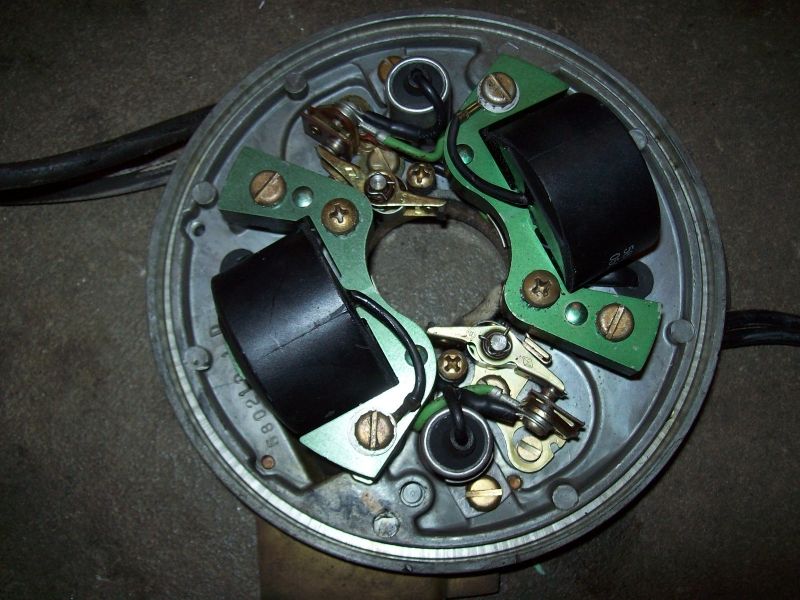

Your coils wires are going to the wrong set of points and condensers. So, your ignition is not in sync and you won't get spark. I have pointed out where the wires should go. Also one of your coil ground wires should be repositioned (I have have a blue line pointing to the correct spot.)

Also make sure your the spark plugs wires are going to the correct cylinder. Look back at the diagrams I posted earlier and that should help you out.

*** Make sure you tuck the wires out of the way so they do not become damaged. If they become damaged, then you will have a short in your system and then no spark

You are almost there!!

Once you have the coils wires position correctly, then you should get a minimum of 1/4 inch spark jump on the spark checker. Nice snappy blue spark!!

I noticed you do not have a oil wicker in place. That helps lightly lubricate the riding surface of the point cam so the points shoes do not prematurely wear out. Go back and look and read the explanations and diagrams I originally posted.

Look, here is a picture of ignition plate, that is how yours should look. See, the orientation of the wires and they are tucked away.

After you have repositioned the wires as indicated, please post another set of pictures so we can make sure all is well!! Want to get you on the water too!!!