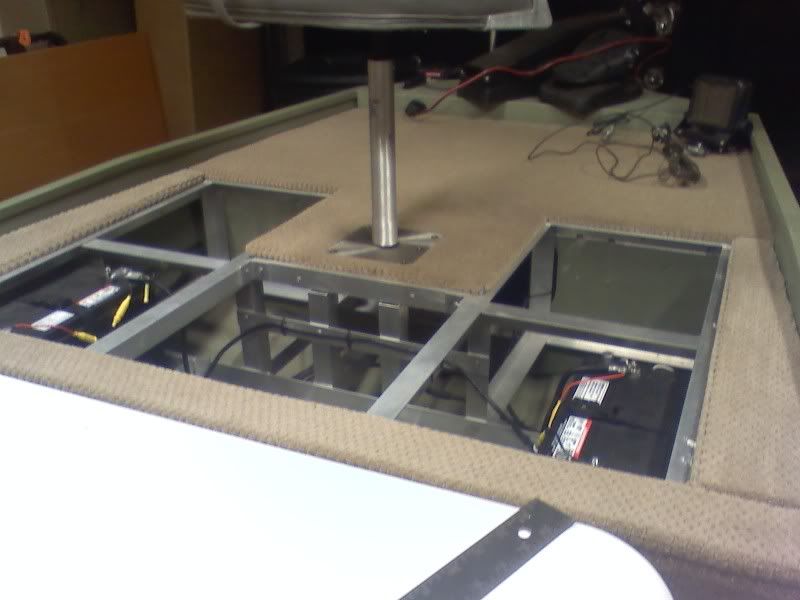

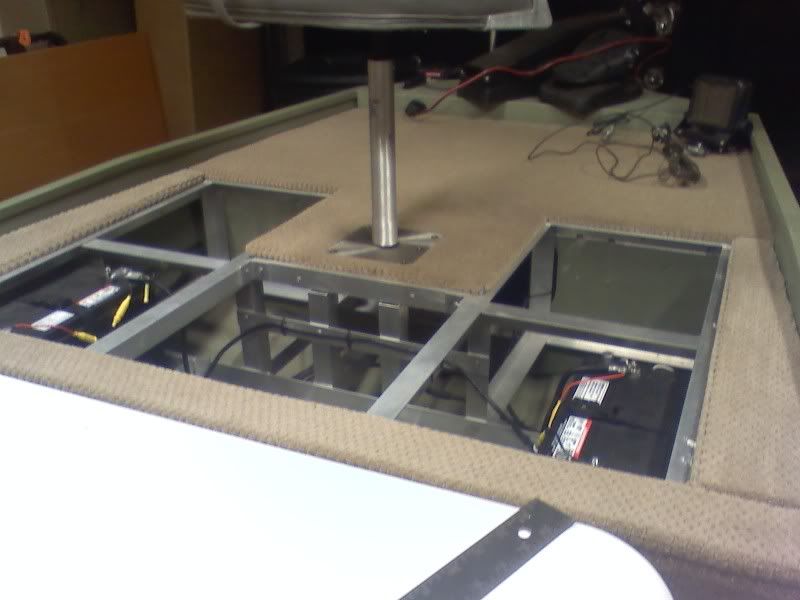

Well, here we are almost 7 years later, and I'm embarrassed to say that shortly after my last post, I caught the golf bug again. So that was the effective end of my conversion project (I can only obsess over one thing at a time). Hey. but at least I got my handicap down to an 8.3! 8) Anyway, here's a rough idea of where it sits right now, although I do have several of the hatch lids made and carpeted that aren't shown in the pics. I used flush-mount hatch handles and stainless steel piano hinge.

As you can see here, this thing is all aluminum. Completely water proof and sturdy as hell!

The material used to mount the livewell switch below is an example of the skateboard ramp composite material that was used for the decking. Also completely waterproof and UV resistant!

Now to the reason for the post update...

The wife is screaming to get this thing out of here. Either put it in storage or sell it. I'm leaning toward putting it into storage, but a coworker is interested in possibly buying it as-is; he's a handy guy and finishing the last few little things won't be a problem for him. This sale includes all materials (far more than enough to finish the project up), and I have absolutely no clue what a fair price might be and I'm hoping some of you can help me out.

So what do you guys think? What do you think the market will bear? What's a good price that ensures we both get a fair deal? Maybe one price with the outboard and one without? I can always sell that separately.

Thanks in advance for any help / advice you can provide!