ClemsonAlum

Well-known member

- Joined

- Dec 30, 2019

- Messages

- 57

- Reaction score

- 0

I have a suspicion my upper crankshaft seal is blown or damaged. Also, this motor has low compression, 40 PSI nearly exactly on both cylinders, cold, using a Harbor Freight compression tester.

Edit** just found out my tester is not accurate, need to get another one. Will update thread later when I get an accurate one.**

The low compression may be a separate, but I will give more info below. Any wisdom shared to help me confirm this is appreciated!

Here is some history and pictures.

It is a 1973 Evinrude 9.5. Runs about 12 MPH with 8" x 7 pitch prop on old 1436 Polarcraft, by myself, with battery behind front bench, gas tank as far forward as possible, and about 75 lbs fishing stuff. I built a transom riser to get the Cav plate on plate with bottom of boat. Drafts about 6-8" in back idling. Will not get on plane by myself (may be due to just older motor + my 200 LB butt in the back of the boat).

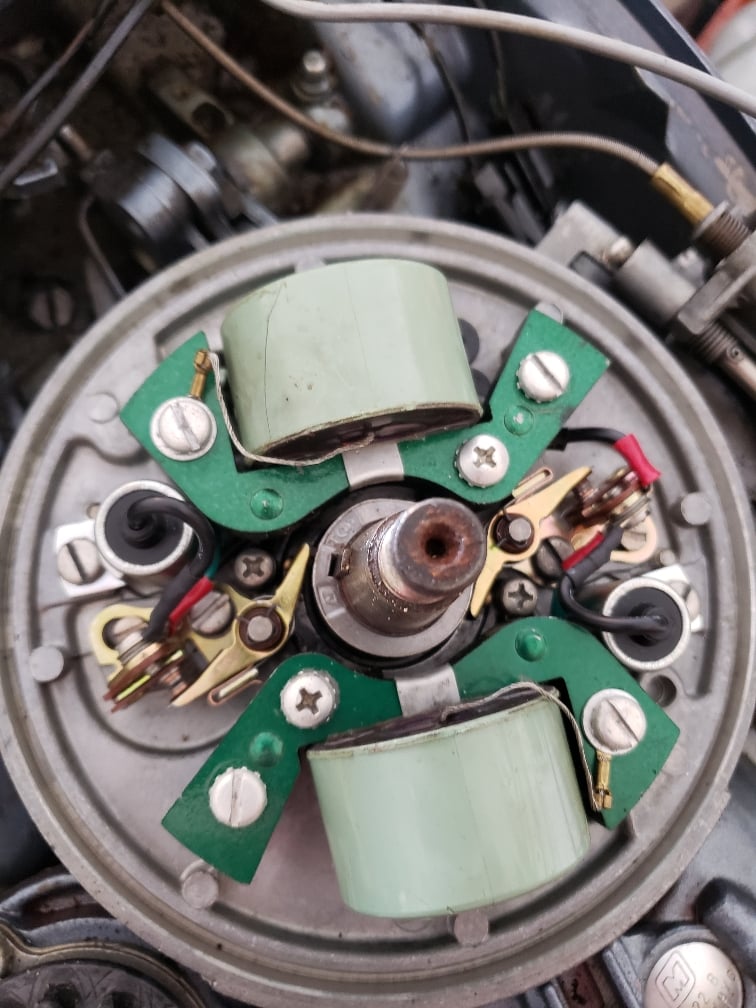

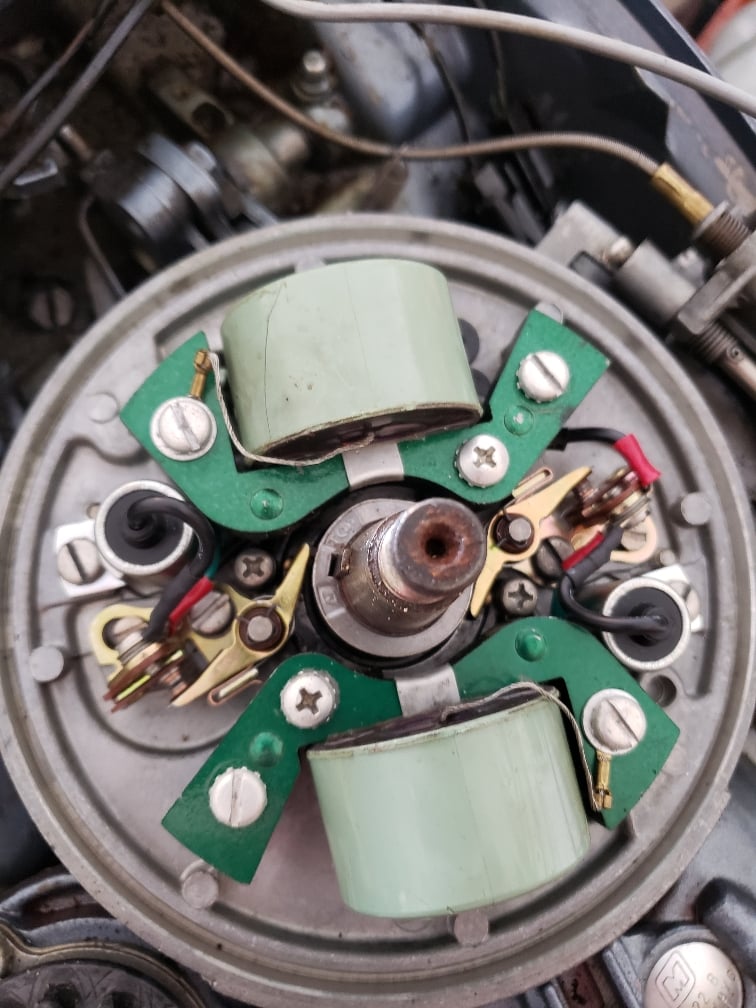

Today I took off the flywheel to check if the Shear Key got sheared when I hit a log and spun the prop hub the first day I took it out. Oops. Anyway the points were checked and they were good, 0.020 and no corrosion. Looked new.

I lifted up the timing plate to look for tell-tale oilly residue. I think I saw some, but there is so much other 50 year old grease and residue under the cowl due to previous exhaust leak, fuel pump leak, and miscellaneous grease due to all the fittings. You be the judge please (see below).

As for issue #2 Low compression, both cylinders, 40 PSI. Plugs visibly wet. Low speed idle is set per usual instructions. Otherwise it runs pretty good, reliable, just hard starting. Got this motor in October last year and has only gave me trouble once when it flooded idling (think this is separate issue, shellac on the float was gone when I cleaned the carb when I got the motor). Causing float needle to not seat and flood. Or it could have been due to diaphragm in fuel pump breaking. Either way, it hasn't gave up on me much.

The pull start is firm and you get the usual resistance when you turn the motor over.

So I think low compression is due to one of three things. Hopefully I can diagnose without taking the heads off? Maybe with a loan a tool inspection camera from the auto parts store? Any advice appreciated.

1. Blown head gasket between the two cylinders.

2. General wear on piston rings since it is so old and used (I don't think they are stuck since compression is consistent between cylinders?)

3. Related to possible blown upper crankcase seal? I just started learning about these 2 stroke motors, so I may be wrong?

-Kurt

14', 1960 Polar Kraft, '73 9.5 Evinrude

Edit** just found out my tester is not accurate, need to get another one. Will update thread later when I get an accurate one.**

The low compression may be a separate, but I will give more info below. Any wisdom shared to help me confirm this is appreciated!

Here is some history and pictures.

It is a 1973 Evinrude 9.5. Runs about 12 MPH with 8" x 7 pitch prop on old 1436 Polarcraft, by myself, with battery behind front bench, gas tank as far forward as possible, and about 75 lbs fishing stuff. I built a transom riser to get the Cav plate on plate with bottom of boat. Drafts about 6-8" in back idling. Will not get on plane by myself (may be due to just older motor + my 200 LB butt in the back of the boat).

Today I took off the flywheel to check if the Shear Key got sheared when I hit a log and spun the prop hub the first day I took it out. Oops. Anyway the points were checked and they were good, 0.020 and no corrosion. Looked new.

I lifted up the timing plate to look for tell-tale oilly residue. I think I saw some, but there is so much other 50 year old grease and residue under the cowl due to previous exhaust leak, fuel pump leak, and miscellaneous grease due to all the fittings. You be the judge please (see below).

As for issue #2 Low compression, both cylinders, 40 PSI. Plugs visibly wet. Low speed idle is set per usual instructions. Otherwise it runs pretty good, reliable, just hard starting. Got this motor in October last year and has only gave me trouble once when it flooded idling (think this is separate issue, shellac on the float was gone when I cleaned the carb when I got the motor). Causing float needle to not seat and flood. Or it could have been due to diaphragm in fuel pump breaking. Either way, it hasn't gave up on me much.

The pull start is firm and you get the usual resistance when you turn the motor over.

So I think low compression is due to one of three things. Hopefully I can diagnose without taking the heads off? Maybe with a loan a tool inspection camera from the auto parts store? Any advice appreciated.

1. Blown head gasket between the two cylinders.

2. General wear on piston rings since it is so old and used (I don't think they are stuck since compression is consistent between cylinders?)

3. Related to possible blown upper crankcase seal? I just started learning about these 2 stroke motors, so I may be wrong?

-Kurt

14', 1960 Polar Kraft, '73 9.5 Evinrude