Ranchero50

Well-known member

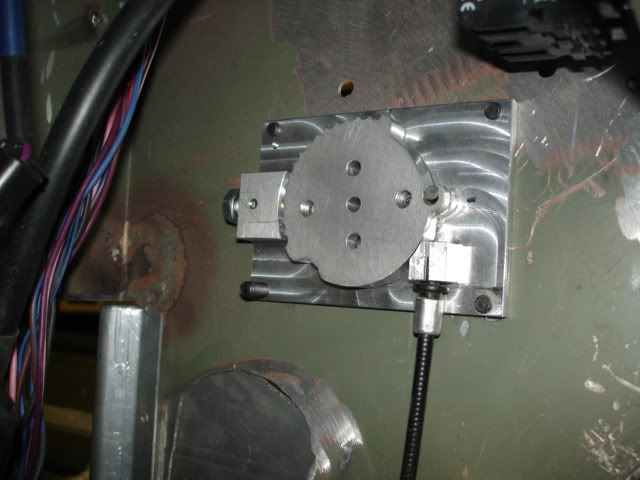

Console Round IV

Doesn't seem like much got done, but the console mounting sides are done. I put the motor and pump back in and routed the steering, throttle and choke cables and played with the exhaust a little more. I also added the steering shaft below the U joint. The console will be removable when done if needed.

Further... If I have enough room I'm thinking about adding another panel under the switches to install a stereo. I also added a toe board for the floor which hopefully a fish won't flop over and get lost under the floor...

Motor back in the hole and I decided to just stick the muffler on the back of the expansion pipe. benefit being the port rear storage just got so much larger.

Throttle lever is going to have to mount around the two holes in the side, a little lower than I wanted, but I only have so much cable to play with. I'll just have to make some kind of Ed Roth cool azz handle to give 'er some fuel with...

More to come Monday if not sooner, got to work sometime...

Jamie

Doesn't seem like much got done, but the console mounting sides are done. I put the motor and pump back in and routed the steering, throttle and choke cables and played with the exhaust a little more. I also added the steering shaft below the U joint. The console will be removable when done if needed.

Further... If I have enough room I'm thinking about adding another panel under the switches to install a stereo. I also added a toe board for the floor which hopefully a fish won't flop over and get lost under the floor...

Motor back in the hole and I decided to just stick the muffler on the back of the expansion pipe. benefit being the port rear storage just got so much larger.

Throttle lever is going to have to mount around the two holes in the side, a little lower than I wanted, but I only have so much cable to play with. I'll just have to make some kind of Ed Roth cool azz handle to give 'er some fuel with...

More to come Monday if not sooner, got to work sometime...

Jamie