Well I got some serious work done on the boat this last week! The pictures make everything look easy but it takes a lot of time and work to do these rebuilds. I guess for me it takes twice as long, I can't settle until its perfect.

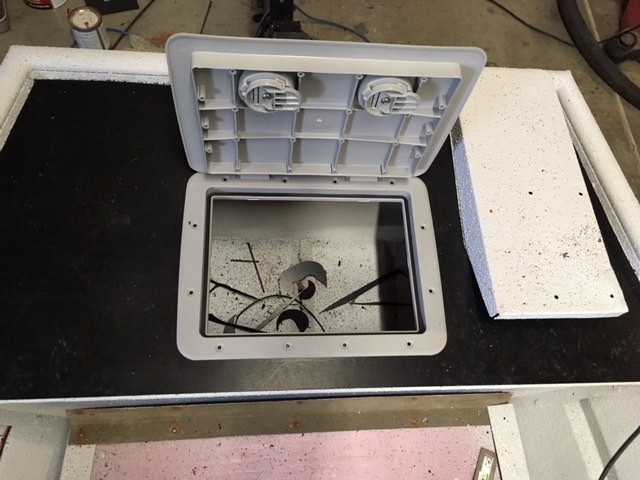

Took a while but I got the flooring cut out and ready for epoxy resin. This really won't add too much strength but it seals the wood up nice. I thinned it with acetone and did two coats to make sure it soaked in.

Second coat done and drying. This is the part I hate, can't do ANYTHING until its cured.

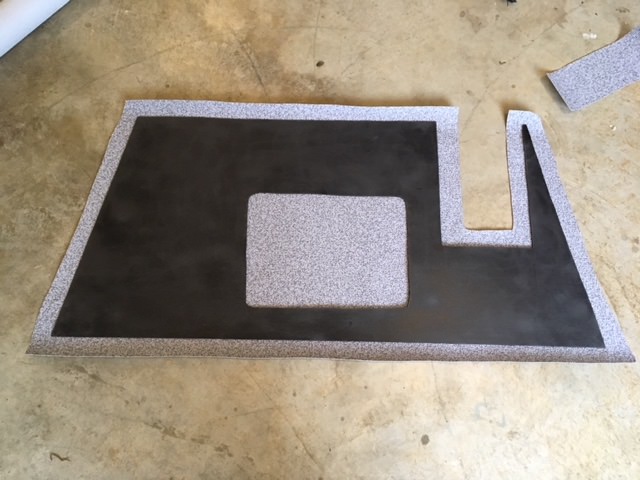

Now we have the wood all sealed up nice it's time to lay out the vinyl and trace out what I need. This Nautolex Marine Vinyl Flooring is not cheap so I make sure to measure twice and cut once!

Once all that was done I glued and trimmed the vinyl on the flooring and laid it in to see how everything fit. One thing you need to watch out is "tolerance stacking" that is where you add extra dimension from the thin flooring itself and may end up with everything too big. You especially need to watch out on thick marine carpet. Luckly you can stretch the vinyl out and pull it tight so it only adds maybe 1/16".

Floor is all ready to go in so I got it square and started to rivet the floor down to the crossmembers. That was a pretty easy task but cranking down 50 big rivets by hand wasn't too fun.

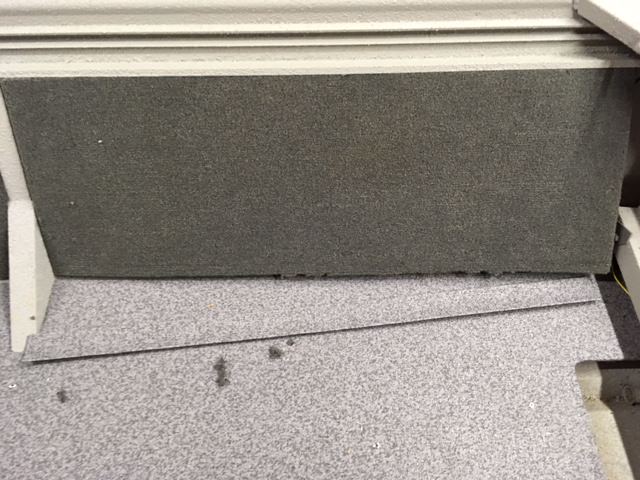

Here's a shot of how the side panels go in, they slip into a channel on top and have a piece of trim that secures everything together. Pretty slick idea.

Installed

Next morning I decided to take a pic of the progress... Floor is all installed but I still need to do the side panels and put the seat bases in as well as other bits and pieces.