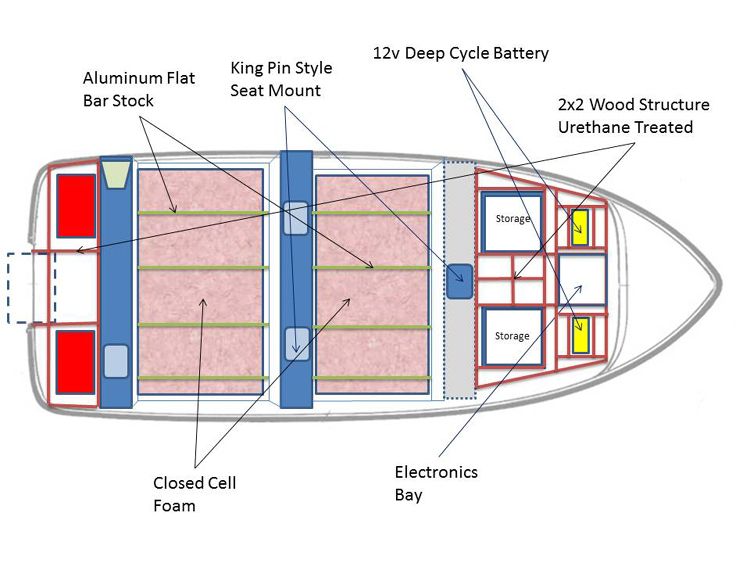

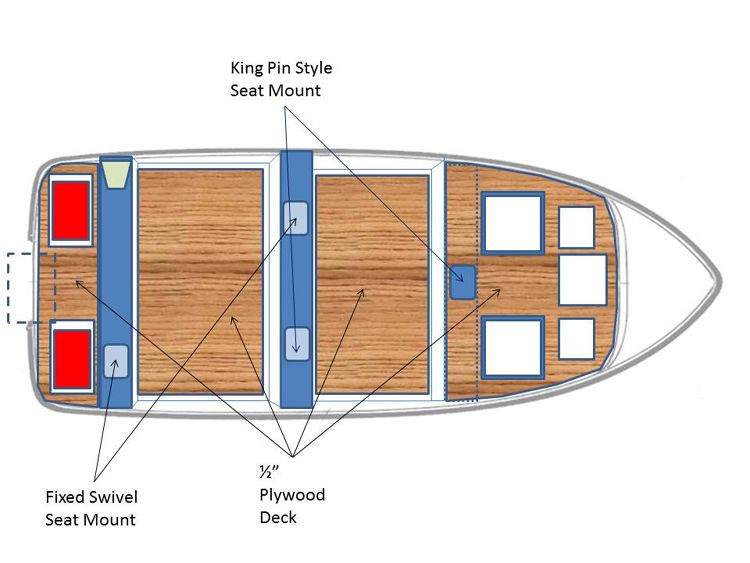

Well, got a lot done this weekend. Finished the sanding on the outside of the boat, finished sanding the repaired spots, (the JB Weld worked great) and the biggest accomplishment is I got the substructure for the center deck installed! I had all kinds of cool plans using tube aluminum, bar stock and so on, but what I actually ended up using was three aluminum rails from a computer server rack system that I picked up as scrap along with some aluminum angle. With that I made a trip to Lowes, picked up some nuts and bolts, a sheet of 19/32 plywood and two 4' x 8' closed cell foam panels.

I ended up cutting out the top of the front seat for a couple of reasons. First, I needed to add some backing/support for the angle I attached to the bottom of the flotation box and secondly I decided to make this my battery box. I figure by installing one or two batteries up front, it will help to balance the load in the boat.

Here is another shot of the rails/channel. I mounted them channel up and I plan to add a wooden insert that the floor and a center seat will eventually be attached to.

After securing it to the front and rear seat with bolts, I used 3/16 x 1 aluminum rivets to connect the cross member to the lower part of the supports where the middle seat used to be and to the rails running fore and aft. Once everything was tightened down it was pretty sturdy and had limited flex. I think it should work out fine and the good part is if it doesn't its just a matter or removing a few bolts, drilling a few rivets and the floor comes right out.

I plan to Gluvit all the seams and then apply 3M 5200 sealant in the transom area and few other places. After that I should be about ready to start primer work and then final painting. Anyway, shes coming along nicely.

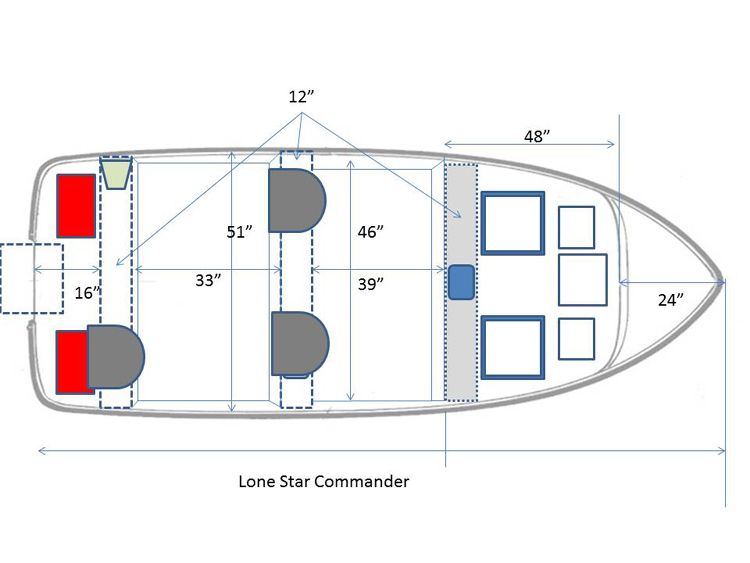

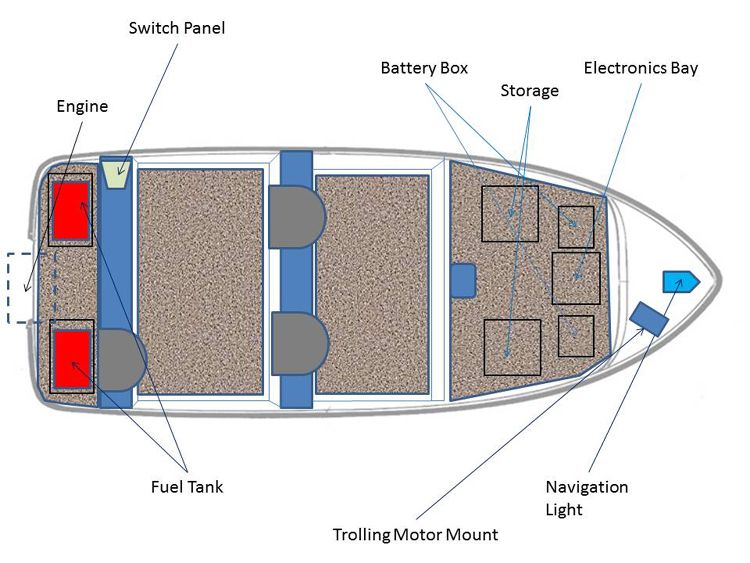

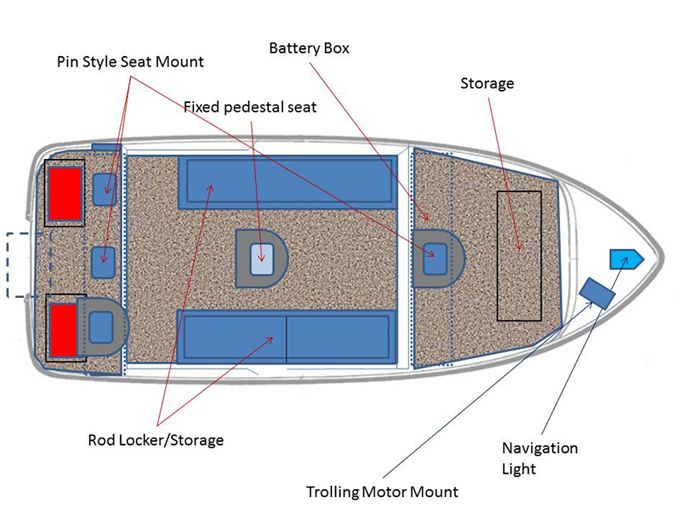

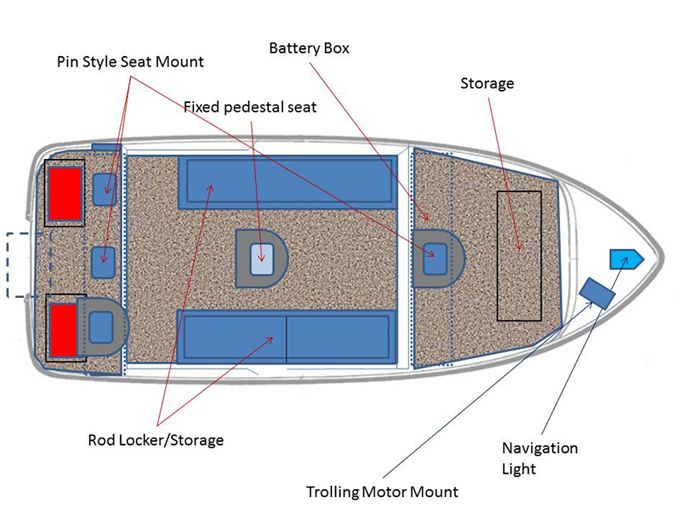

Here's my latest concept of what I'd like to accomplish with the boat, guess we'll see how it works out

Thanks for looking and your comments and questions are welcomed.