ohm

Well-known member

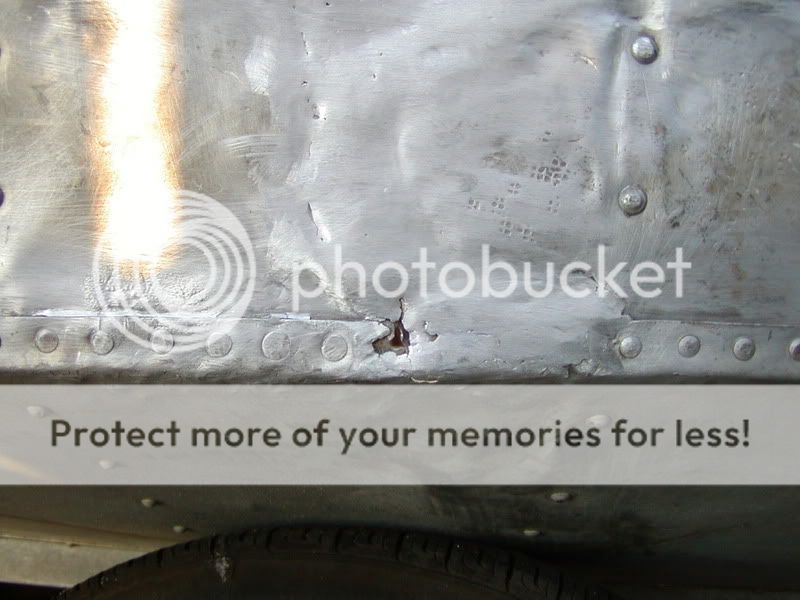

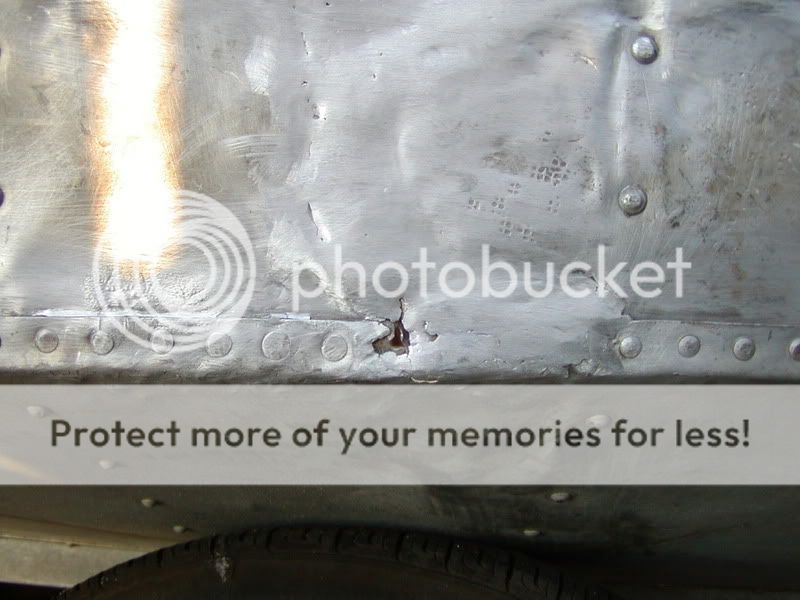

I decided to make another post over here for my hull repairs and I well go back to the other thread when I actually get to modifying the boat. As you may remember my boat had a pretty nasty "repair" job done on it by one of the previous owners and I have been working on getting all the silicone and old weld removed and ground/sanded down. I have that pretty much all done and I now looking at having a couple of the small holes welded in properly. I didn't do too much on the inside of the weld aside from remove some of the more grotesque lumps, the middle seat covers the area anyway, but I got the outside ground down and cleaned up pretty good, still not near perfect but 150% better then it was. I am going to call a guy I know that does metal fabrication and welding and have him weld the small hole closed and also put a fillet bead along the lower seam in the effected area on the inside to make sure it is sealed nicely. Here are a few photos of the area now.

Here is the inside, as mentioned I am just going to have them run a good fillet bead along the seam to ensure that the seam is sealed.

And the outside view, just a small hole about the size of a pencil eraser.

Here is the inside, as mentioned I am just going to have them run a good fillet bead along the seam to ensure that the seam is sealed.

And the outside view, just a small hole about the size of a pencil eraser.