Too bad 3M doesn't make 5200 in a spray can. Could you imagine how tough the hull would be if you could apply a 1/8" thick coating?! Man, you could just about jump stumps with it, and it probably wouldn't even make a dent.

For those of you who have never used 5200, let me warn you, only use it on something you intend to be permanent!! Because you will often destroy the part if you try to disassemble it (learned this the hard way by using it to install a jet pump)

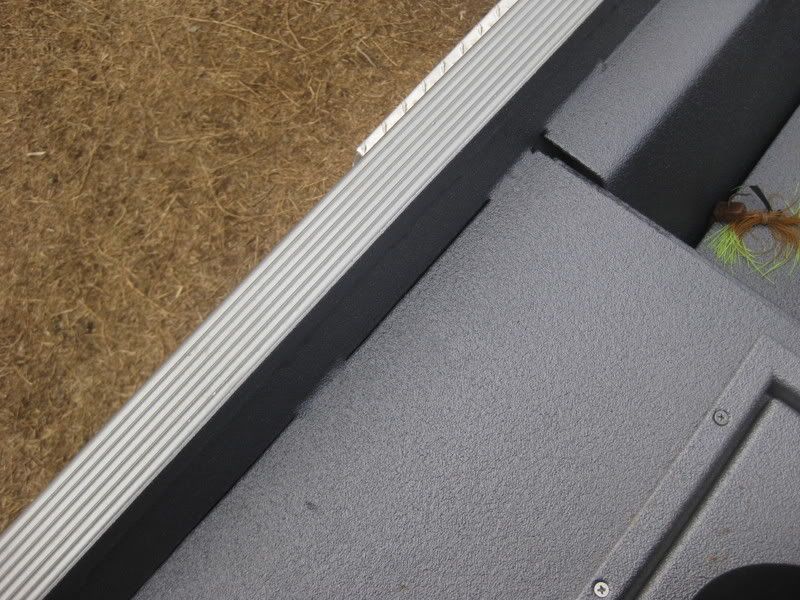

Anyhow, when I dealt with the issues of corrosion on my boat, everything was welded water tight, before I ever applied any truck bed liner to my hull. I used the 2-part stuff from Rust-Oleum.

So, the liner isn't on my hull to stop any leakage, it's mainly on there to protect the integrity of the hull. I thought about having it professionally rhino-lined, but then I talked with someone who had that done to their boat, he said it peeled off. So, I decided I wasn't going to waste the money to have it done, I'll stick with the spray cans.

About every six months or so, I crawl under the boat, and I wire brush any bare metal with a STAINLESS wire brush (it is very important that you use a ss brush to clean aluminum, do not use regular steel!) then I spray those areas with zinc chromate primer (also very important for proper coating adhesion, particularly on aluminum) then I hit it with truck bed liner, and follow up with a thin coat of anti-fouling paint (always use copper thiocyanate paint on aluminum boats, use cuprous oxide only on fiberglass)

And while I'm at it, I check my zinc anodes, and if they're not yet worn down from electrolysis, I will take a grinder with a stainless wire wheel, and run across them to remove oxide to expose fresh zinc for the electrolysis to attack. On my 16 foot jet boat, I use 2 zincs that are 4 inches by 6 inches, bolted to either side of the jet unit tunnel at the stern..... as well as a small Evinrude/Johnson OBM zinc (oval shaped, about 2 inches long by an inch wide) which I attach directly to the bottom of my steering nozzle (I have found that the steering nozzle is susceptible to electrolysis without a zinc, despite zincs being on the boat)

So, any of you who operate a boat in brackish or salt water, if you follow my methods above, you can protect your hull. But once electrolysis starts eating holes through the boat, these types of leaks are difficult to stop, except by welding them, and this is often a PITA, as corroded aluminum does not weld very well at all.