JMill

Well-known member

Lol awesome. What kind of rivets do you plan on using? Solid? Or do they make "pop" style closed end rivets in 1/4" size?

JMill said:Lol awesome. What kind of rivets do you plan on using? Solid? Or do they make "pop" style closed end rivets in 1/4" size?

trackerpuzzle said:

lol thanks - not sure I would have done all that If I would have had to buy the 4x4's , but they worked great .DarynCashmark said:Man, I am loving your cranes, dollies, not sure what the proper terminology is but, wow they are cool! Build is looking good so far brotha!!!

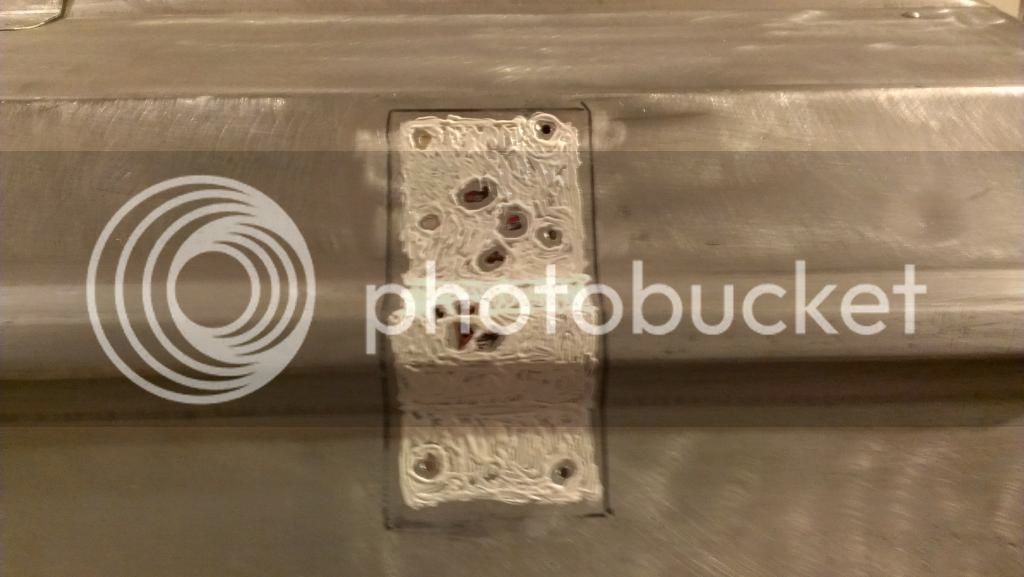

lol haha that will probably be the easiest part of the whole project , don't know what caused the pitting , from what I have read on here could have been from treated lumber being used on the bunks or from letting salt water dry on the bunk carpet(the boat originally came from Georgia) I would give her a peek just for peace of mindJmill said:You've got me worried about my hull where the bunks rest now! Guess I'll be yanking her off the trailer and doing a through search. Sheesh! Does it ever end?? Lol. I'm already scatter brained enough on what I'm going to do each day!

thanks SkiffingSkiffing said:Very nice work. Lot's of elbow grease ...... and other lubrication gets the job done.

yea I think I got the big'ol leaky twin though . Hope it all goes smooth for you !Bigsho69 said:Working on your twin boat. Cant wait to see how yours turns out.

Enter your email address to join: