architorture

Well-known member

Hey guys, I've been hiding around here a while but have never actually introduced myself. This place is very inspiring! I've always wanted a bass boat but after some of the conversions I've seen you guys do on your ol' tins I thought that would be much more fun, gratifying, and cheaper (hopefully). I got my boat back in March but didn't get to really touch it until school got out in May. I've been getting the paint off and trying to clean it up to get ready for paint, which it will have soon hopefully. My plan is to set it up like a bass boat basically, a side console with decks in the front and back. I've already got the steelflex for the bottom, it's just waiting for me to finish my prep work. I know this boat's a 1958 model, but I swear they repainted it a different color every week lol. This has been far more time consuming than I had thought and hoped, and hope I never have to do this step again. I'm just going to post a bunch of pictures of when I got it to the progress I've made so far..

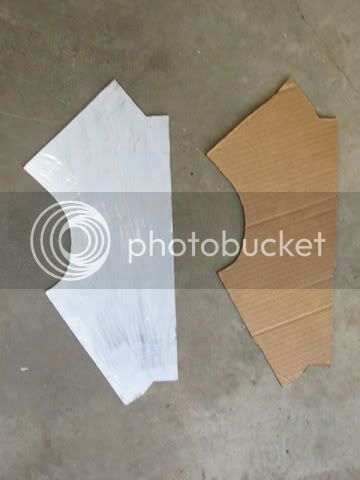

New transom pieces cut from 3/4" ply

Transom gluing.. This is by far the best use I've found for Neverstart batteries

Fit and bolted in with SS hardware. Still need to pick up a few more bolts and it'll be ready to be sealed

Busted weld. Not sure why the PO thought this would hold. They had a 35 horse mercury on it #-o

Transom corner brace cut and ready to be bent

Test fit

Almost done. I'll probably have it welded too so it will be extra rigid

Holes filled with Marine Tex. I think I had somewhere around 55 holes to patch. Someone got trigger happy with their drill!

New transom pieces cut from 3/4" ply

Transom gluing.. This is by far the best use I've found for Neverstart batteries

Fit and bolted in with SS hardware. Still need to pick up a few more bolts and it'll be ready to be sealed

Busted weld. Not sure why the PO thought this would hold. They had a 35 horse mercury on it #-o

Transom corner brace cut and ready to be bent

Test fit

Almost done. I'll probably have it welded too so it will be extra rigid

Holes filled with Marine Tex. I think I had somewhere around 55 holes to patch. Someone got trigger happy with their drill!