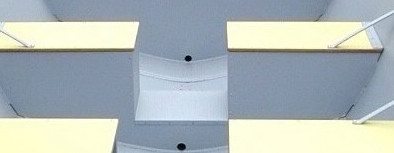

so while i wait for my paperwork, im starting to plan the floor and make marks for where my angle will mount on the front and back of teh existing seats (essentially, where the bottom of my 3/4 ply floor will rest). My question is this - what does everyone level the floor relative too? Since the bow is deeper than the stern, there are several ways i could see doing this

1) What i did but seems off - lay a board across all 3 seats bow to stern with a level on it, and use the trailer jack to level across all 3 seats relative to the ground essentially. Then starting at the rearmost seat cut the widest piece of wood i could across the floor at that seat to maximize the width of the floor, and then mark the bottom of that piece. This is where the back of the floor will start.

I then made the widest piece i could at the middle seat, marked it the same. Then the same for the back side of the front seat. Since the floor tapers toward the front however, and the boat gets deeper, etc, toward the front, this naturally made the front floor slope upward. If i were to make it level to the ground/seats, the floor would have to be narrower the farther forward you go, and you would not be utilizing all your floor space. This is also making the floor level to the ground. Obviously, this is not necessarily how the boat rides in the water.

2) Maybe i should just measure down from the tops of the factory seats at all 3 seats consistently and put the floor supports there. So rear seat measure down 20 inches, mid seat down 20, front seat down 20. While this wont be level to the ground, the floor will always be equi-distant from the seat tops, and i assume the manufacturer made the stock seats to be level to the water, not the ground, so maybe this is best? i would have to play with the height to maximize floor space. The only problem i see here is if i cut the middle seat to make it walk through, it may have a height change through there

3) Measure off something else i am missing here.

Thoughts?

1) What i did but seems off - lay a board across all 3 seats bow to stern with a level on it, and use the trailer jack to level across all 3 seats relative to the ground essentially. Then starting at the rearmost seat cut the widest piece of wood i could across the floor at that seat to maximize the width of the floor, and then mark the bottom of that piece. This is where the back of the floor will start.

I then made the widest piece i could at the middle seat, marked it the same. Then the same for the back side of the front seat. Since the floor tapers toward the front however, and the boat gets deeper, etc, toward the front, this naturally made the front floor slope upward. If i were to make it level to the ground/seats, the floor would have to be narrower the farther forward you go, and you would not be utilizing all your floor space. This is also making the floor level to the ground. Obviously, this is not necessarily how the boat rides in the water.

2) Maybe i should just measure down from the tops of the factory seats at all 3 seats consistently and put the floor supports there. So rear seat measure down 20 inches, mid seat down 20, front seat down 20. While this wont be level to the ground, the floor will always be equi-distant from the seat tops, and i assume the manufacturer made the stock seats to be level to the water, not the ground, so maybe this is best? i would have to play with the height to maximize floor space. The only problem i see here is if i cut the middle seat to make it walk through, it may have a height change through there

3) Measure off something else i am missing here.

Thoughts?