Rdtolbert

Active member

- Joined

- Apr 28, 2014

- Messages

- 28

- Reaction score

- 0

Wanted to start out by saying thank you to those who have provided this library of good information. I am positive this site will cut hundreds of wasted dollars and hours from my build.

I am about to start converting my Polar Kraft, into a cat-fishing boat. The boats main purpose, is running shallow rivers with a 30/20 jet outboard (Also will be used to drift fish small lakes). I purchased the lightest boat I could find(that could run a jet), due to the nature of the area, the boat will be launched in. We have no boat ramps on the two rivers I run, and the few places I have access, are super steep. The boat will be pushed down a 135-170 degree bank, and winched back up. My 3 primary objectives in this build; are to stay light, look sharp, and maximize usability.

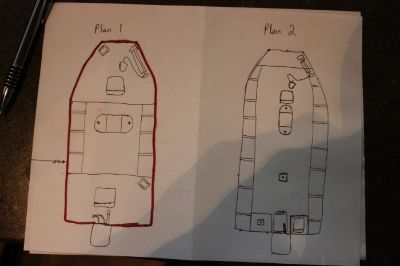

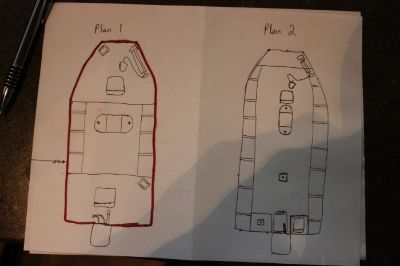

Here are the two rough plans I have in my head. The first builds two casting decks, and leaves an area in the middle for a baitwell. This plan 1 design maximizes trolling motor usage, and makes the boat more versatile. The second design is the lightest, and focuses on using multiple rods for cat fishing.

Here is the boat. With either floor layout, I plan to remove the middle seat, and rear deck. Both seats are filled with foam and take up precious square footage.

Before I start, I could use some advise.

1. To my fellow cat fisherman out there. If you have experience with various boat floor plans, what would be the idea way to lay this boat out? I plan on using multiple rods at times, and want to maximize that cat slaying functionality.

2. Would aluminum decking save enough weight, to justify the price tag? If so, how should it be attached to the support beams?

3. What would be the best way (looks clean and is sturdy) to install a 3"-4"transom riser, without sending it to a shop or using a welder?

4. What is the best way to remove carpet adhesive from aluminum?

Thanks in advance

I am about to start converting my Polar Kraft, into a cat-fishing boat. The boats main purpose, is running shallow rivers with a 30/20 jet outboard (Also will be used to drift fish small lakes). I purchased the lightest boat I could find(that could run a jet), due to the nature of the area, the boat will be launched in. We have no boat ramps on the two rivers I run, and the few places I have access, are super steep. The boat will be pushed down a 135-170 degree bank, and winched back up. My 3 primary objectives in this build; are to stay light, look sharp, and maximize usability.

Here are the two rough plans I have in my head. The first builds two casting decks, and leaves an area in the middle for a baitwell. This plan 1 design maximizes trolling motor usage, and makes the boat more versatile. The second design is the lightest, and focuses on using multiple rods for cat fishing.

Here is the boat. With either floor layout, I plan to remove the middle seat, and rear deck. Both seats are filled with foam and take up precious square footage.

Before I start, I could use some advise.

1. To my fellow cat fisherman out there. If you have experience with various boat floor plans, what would be the idea way to lay this boat out? I plan on using multiple rods at times, and want to maximize that cat slaying functionality.

2. Would aluminum decking save enough weight, to justify the price tag? If so, how should it be attached to the support beams?

3. What would be the best way (looks clean and is sturdy) to install a 3"-4"transom riser, without sending it to a shop or using a welder?

4. What is the best way to remove carpet adhesive from aluminum?

Thanks in advance