So after taking some time off to work on other home projects I got some free time to work on the boat this week. She's coming together nicely and nearly done!

After the Steelflex was done curing I installed a bow eye since I removed the handle that was previously on it. On the inside of the hull I added a thick plate of aluminum for more support. I sealed around the bolt and the whole plate with marine silicone sealant.

Next I started on building the front deck. I cut out pieces for the top of the deck and the inside facing and coated them with spar urethane. On the inside facing I routered holes for the instrument panel, an LED light, and the trolling motor plug receptacle. They may look crooked in the pictures but that's before the boards were carpeted and the pieces were secured. Just for reference though!

I got the top of the front deck cut and carpeted. I cut out a large hatch in the middle of the deck to access the storage area below.

Then I placed the front facing up to it to see how it fit.

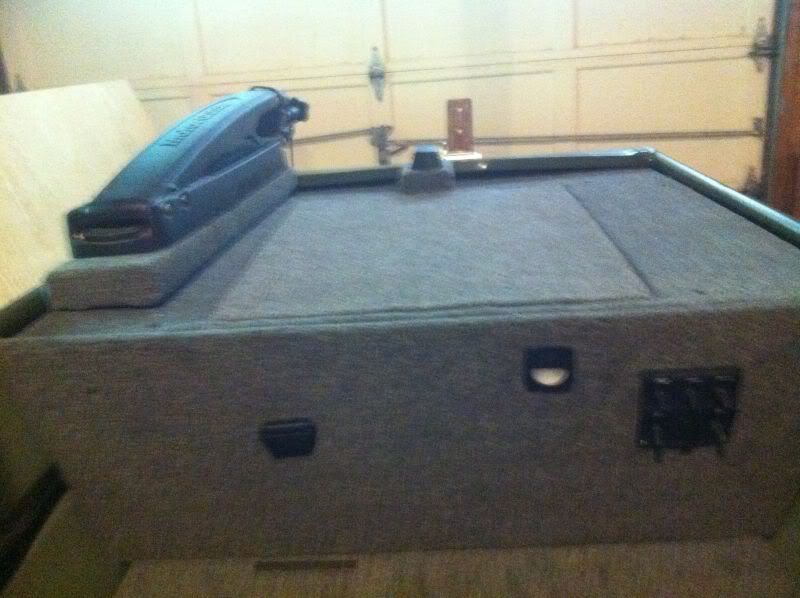

I cut out another piece for the rear bench, urethaned and carpeted it. I secured it to the bench seat with hinges riveted in the back of the bench seat. I'm using a Swivleze system so I mounted a baseplate for the rear seat in the middle of the bench. On the underside I installed the rubber clamps to hold the stern light for storage. (If anyone is curious about the thickness of wood I used, I went with 3/4" sanded pine on the top of the front deck and 1/2" for the inside facing of the deck).

I carpeted the hatch and put it in to see how it fit. I also installed the trolling motor mount at this time. I had to make a mount for it instead of just securing it to the deck 1) because it's sturdier and 2) because I needed to raise up the motor base a few inches to clear the lip of the bow. For the trolling motor mount I used just a piece of 2x6 watersealed and carpeted. I installed it by ratcheting galvanized lag screws through the trolling motor base plate, through the 2x6, and lastly through the deck.

And finally the front facing panel was carpeted and ready to secure to the frame!

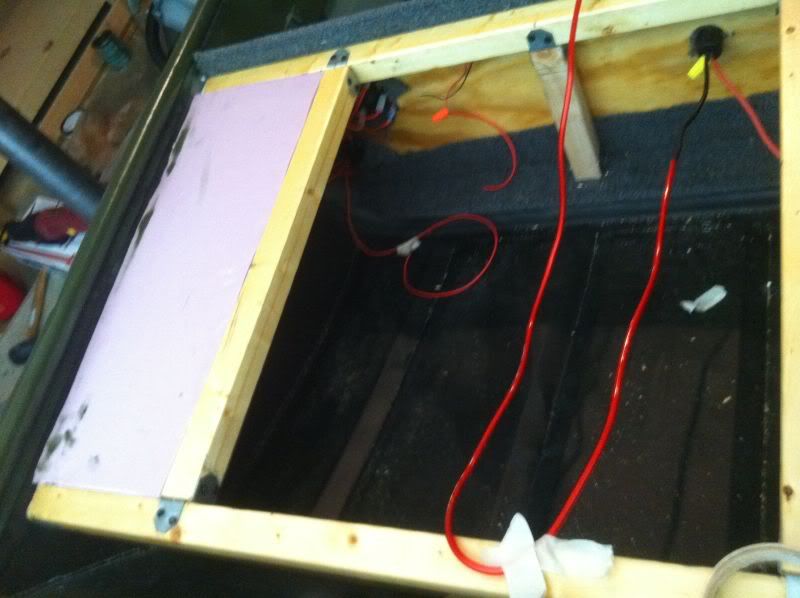

A few shots of the wiring inside:

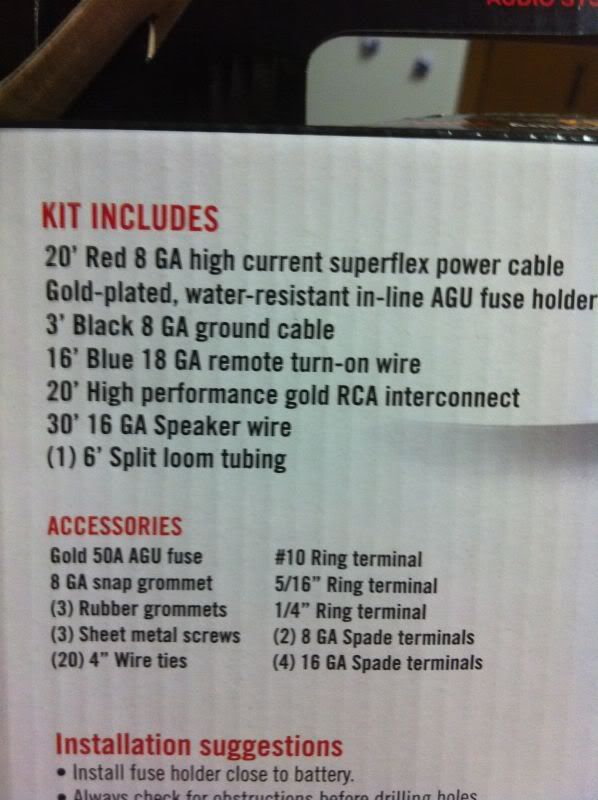

This is the back of the trolling motor receptacle plug. It's a 3 wire plug for 12/24 volts and a ground. Since my trolling motor is 12V and I didn't want an extra wire dangling around I cut it down and capped it with a wire nut. The power and ground cable going from the receptacle to the battery is an 8 gauge insulated wire from a car amplifier installation kit. The wires were soldered and heat shrink wrapped on both ends.

Here is the switch panel. I went with the Seasense 5 gang panel with a 12v cigarette lighter port. I will use this port to power my cooler livewell when it's done. It looks chaotic down here but I'm in the process of getting all the wires secured to the frame and tucked away.

Another shot inside the storage compartment.

I made a little elevated carpeted base for the new bow light. It came with a shiny chrome finish which I didn't like, so I coated the outside with truck bedliner. Gives it a rough more durable surface and looks cooler!

Stern light base installed and the edges sealed with silicone sealant.

As I mentioned I'm doing a locking pin Swivleze pedestal system for both seats. Main reason is that I had all the parts laying around from a previous project boat! I also prefer them to the thicker stationary pedestal stands because those cannot be removed whenever you want to. One issue I faced was the forward seat. The pin goes below the base about 2" when the pedestal stand is inserted in the base. There wasn't 2" for it to go down in the middle of the floor, so I had to raise it up. I made a carpeted block with a piece of 2x8" for the base to mount ontop of. I used a drillbit for boring holes in doors to go all the way through the block so the base and pin could sit flush. Carpeted it up and secured it to the floor. I think it came out pretty good!

Here's some more photos of what it looks like now:

Here's the red LED light I got for the boat. I actually got 3 of them; one on the front and two on the sides. I went with the red because I've heard the white/blue is a little bright for the night vision when you're fishing after dark. I still have 2 to install so I'll see how it looks when all 3 are in.

Front and stern lights on.

Storage under front compartment. I'm going to fill any free space with closed cell foam or lifevests/seats.

Trolling motor.

So that's where I'm at right now! Still have a couple more little tasks to do. I'm debating on whether I wanted to carpet sideboards to go from the floor to the gunwales to hide all the wire, but I'm not sure I want to do that anymore. I don't like the exposed wire tubing showing though; doesn't look clean to me. I should have her out on the water early next week!