Hey there fishinmich, should have sent me a PM, I'm on everyday but havnt checked this thread casue I didnt have any updates. Sorry.

Been working on the boat all weekend.

Yesterday, I pulled it out of the garage and put it on some horses. I put 4 or 5 inches of water in it and found several leaky rivets. I marked them all and brought the boat back inside for some rebucking. After that I spent a couple hours with my grinder and a cup brush cleaning up the bottom of the boat. I sandblasted last year but it has sat bare ever since. I wanted to make sure I got all the oxidation off so I would get a good bond with the steelflex.

This morning, I woke up ready to steelflex. Ive kinda been dreading it after reading the "everything steelflex" thread front to back. That thread had me a little gun shy!! I'm here to say, that stuff isnt near as hard to work with as let on by some folks in that thread. It definately isnt the same as painting but its not bad at all. Then again the temps were around 90 today with roughly 90% humidity so I'm sure the humidity gave me a little more time to work with it than some others have experienced. I dont have any pics of the process because I was a nervous wreck and didnt want to have to deal with the camera. Also the stuff is REALLY messy and I wouldnt have touched the camera anyhow.

I didnt like the olive drab color that I chose after seeing it on some other rigs here. I was looking for something a little closer to what todays olive drab is. I chose to not use all of the pigment. I used a little less than half of the pigment. Its still darker than I wanted but overall, I'm happy with it. I'd call it more of a forest green than an olive drab or army green which is what I believe thier olive drab really is. Also, lots of people steelflexed thier entire boat with 2 coats and still had some left over for touchups. For the life of me, I cant figure that out. I must have gotten a little carried away with it. I only did the bottom of my boat, 2 coats and I used the entire gallon. Actually had to go back and scrape the cans to get the last little bit to finish up. I did have about a half a cup get wasted after mixing up too much at the end of the first coat. I gaurantee it not to leak!!!! LOL

Heres the end result after finishing the steelflex...

When I get the boat flipped back upright in the next day or so, I'll get pics of the welding I had done. I completely forgot about it when I had it flipped upright yesterday.

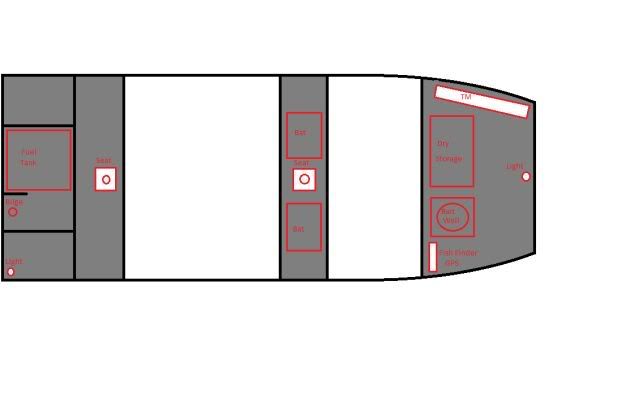

Were chugging right along now. I ordered a ton of stuff from Bass Pro that has all gotten here so I just about have everything I need to completely finish my project. Hopefully she'll be done in time for the fall Crappie bite!!!