Hello my name is Josh. Ive been lurking here for the winter gathering ideas and info to restore my new to me Sylvan Backtroller. I purchased the boat late last summer knowing the floors were about shot. My goal here is to install new wood and vinyl/carpet.

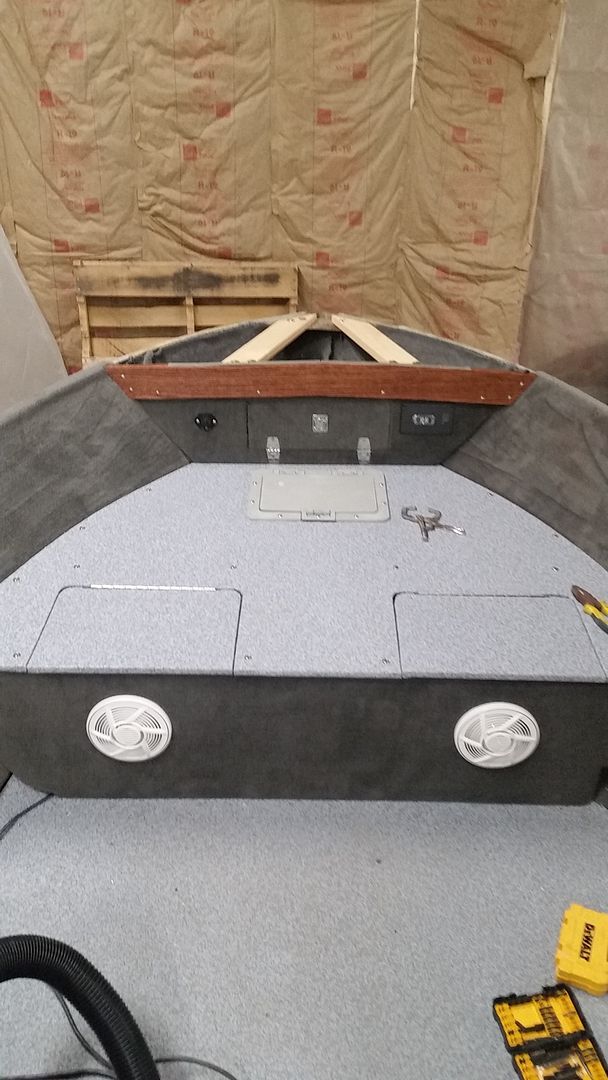

Hello my name is Josh. Ive been lurking here for the winter gathering ideas and info to restore my new to me Sylvan Backtroller. I purchased the boat late last summer knowing the floors were about shot. My goal here is to install new wood and vinyl/carpet. The boat is in good working order aside from the original floors that need to come out. The boat has a yamaha 50 pro that runs great. Also included was a minn kota power drive 50 that works well. I have only fished the boat a handful of times and like the layout so I wont be changing much there. The boat doesn't appear to have any leaks. I always pull the plug on the ramp and have yet to have any water come out. I will be changing out the bilge and livewell pumps just for peace of mind even though both work. I plan on using marine vinyl on the main floor and marine carpet for the rest. I think Im going to use exterior grade plywood and seal with a recipe I found here consisting of spar, linseed oil, and mineral spirits. After spending the last two days pulling out old corroded aluminum rivets I think the new wood will be screwed down using stainless hardware. I would like to add some storage under the bow casting deck to allow me to move the batteries up front. I will probably run some extra wires around for future projects. I was able to get the boat to my brothers shop Monday morning and started tearing everything down. I have this week off work and would like to get as much as possible done.

I do have a couple questions:

1. The wood in the boat is really water logged. The wood sits on top of the factory pour in foam. I dug around a few spots down to the hull through the foam and could only find about 1/4" of foam where the wood was sitting on it that appear to be holding water. With the other 4" of foam dry, is this something I should tear out and replace or will this top layer of foam dry before the new wood goes on?

2. Say I wanted to fill the boat for a leak test, could I do so with the factory foam still in the boat? If that's possible I would fill the boat to the water line and if any leaks were found I could just remove that section of foam for the repair.

When finished the boats main purpose will be chasing trout, panfish, and bass in the Finger Lakes region of NY.

As this is my first boat project of any kind and questions, comments, or suggestions are greatly appreciated. I will try to load some pics of when I bought the boat and where I am as of today, but I'm not the most computer savvy guy.

Josh