I got the boat back from the fabricator this morning. So much to talk about!

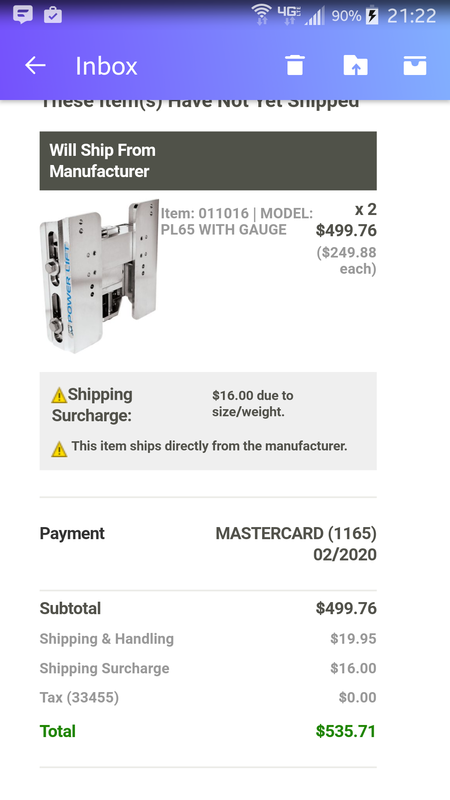

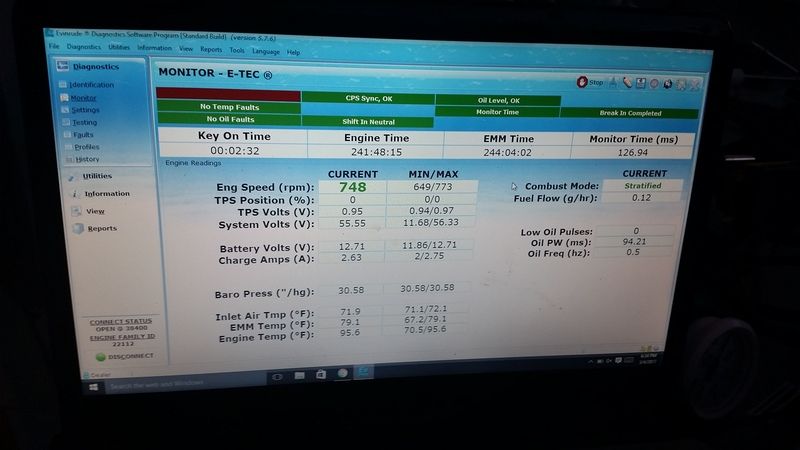

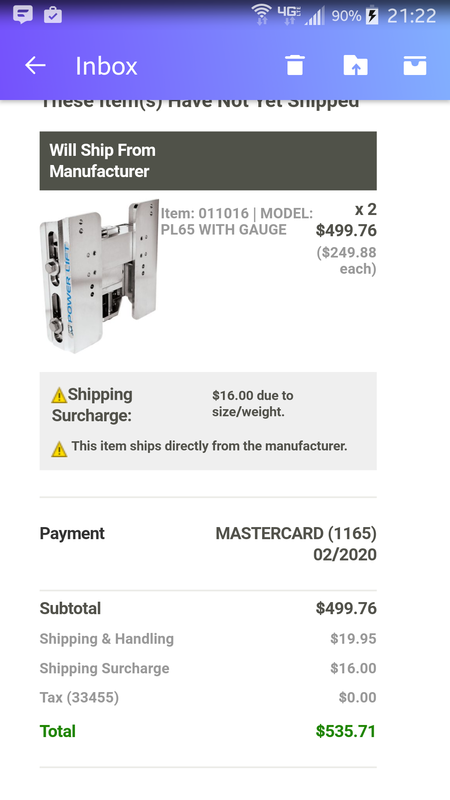

First, I was cruising the web looking at manual jack plates. I've been wanting one bad, but at over $200 it just wasn't a priority. So I'm doing some research and I come to the Cabela's site. I just about fell out of my chair when i saw this:

Yes..they're hydrolic and even come with a position guage for the console. $250??? Regular price was $1000!

So I bought two...LOL

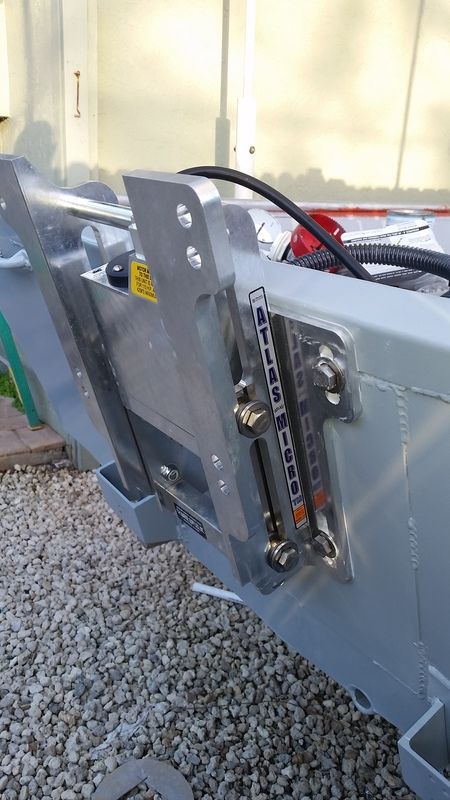

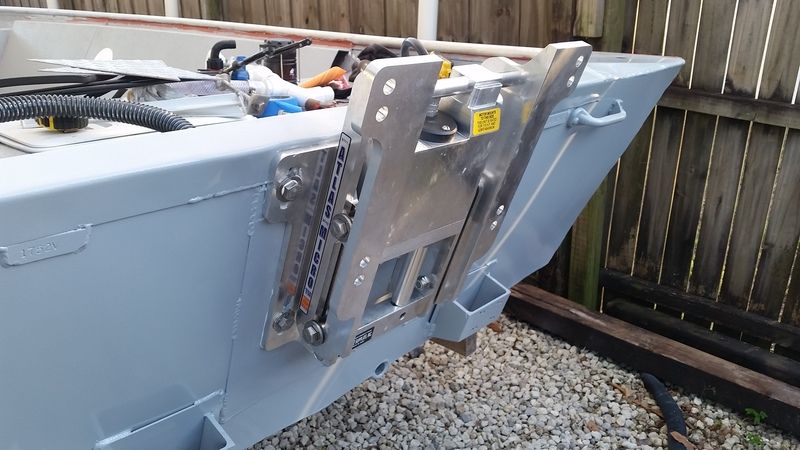

Ok, now I can tell you about the fabrication. I wanted the space between the rear bench seat, and the transom framed. Mainly so I could deck that area to add more fishing space. But also to support the bench seat itself, and the transom. I need the extra strength in the transom now that a 42 lb jack plate will be hanging off the back. The framing is 2" square tube, with T stock in the middle. This deck is SOOO strong. On top is .125 aluminum. My plans are to rivet the .125 down with 1/4 rivets, and install 9" inspection covers like this.

Here's the framing:

And the decking over it.

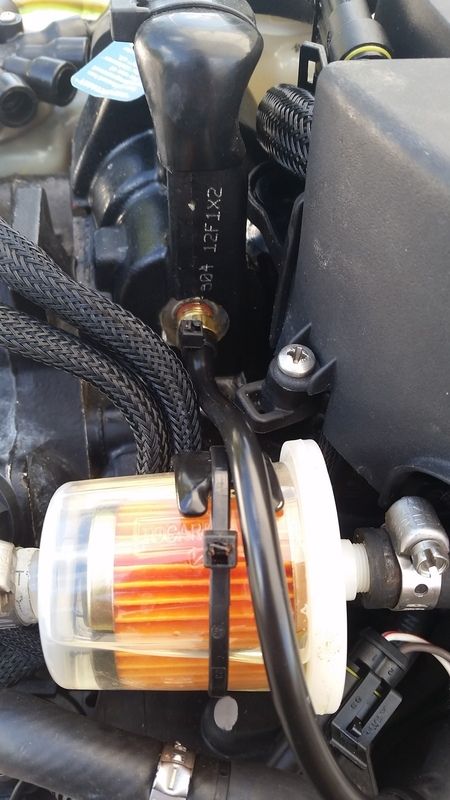

Then there's the fuel cell. I promise you won't find another one like this. If my math is correct it's just over 5 gallons. It'll bolt in so I can clean/service it later on down the road. There's rubber anti fatigue mat under the fuel cell to keep it from chattering. This, along with the battery being mounted up front should offset a lot of the weight from the rear deck and console.

And the battery mount. I keep wanting to call it a tray. It's supported by 1" square tube underneath.