mbweimar

Well-known member

Update:

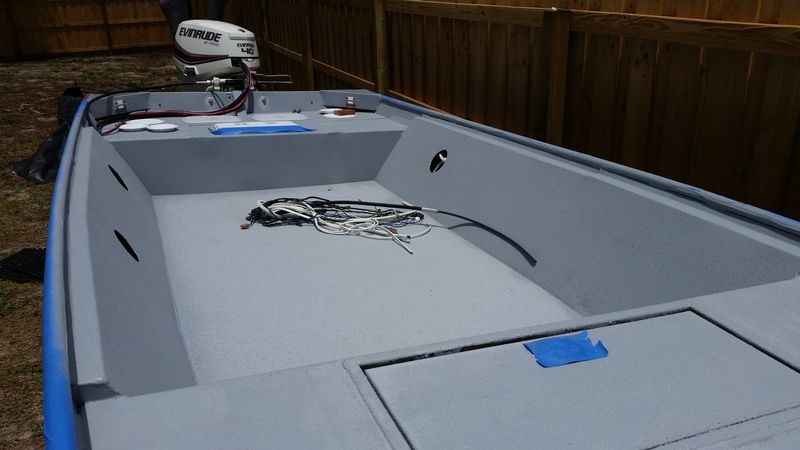

Lots has been accomplished in the last couple weeks since I checked in. Once I got the engine hung, I start d working on the rigging. I bought new shorter shift cables from Amazon, and a shorter 12' steering cable. Turns out the steering cable was too short and I had to exchange it for a 13'.

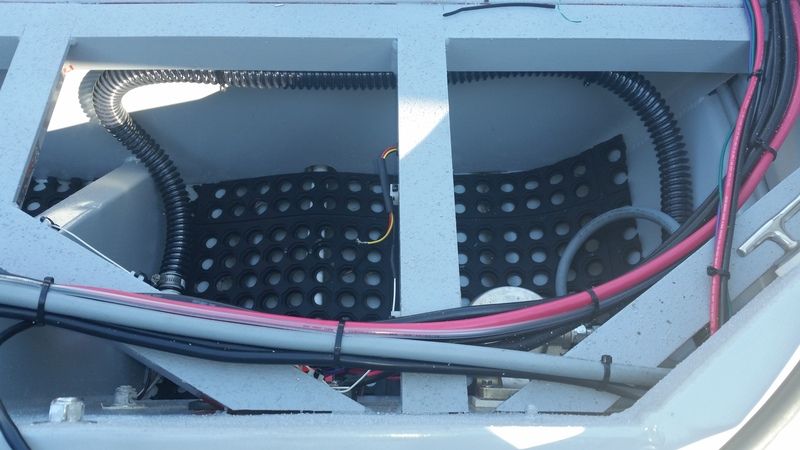

The starting battery has been relocated up front for better weight distribution, and that called for an upgrade to the existing batter cables. I purchased about 17' of 2/0 battery cable for the run. I had a heck of a time fitting it through the rigging gromet, but I made it work.

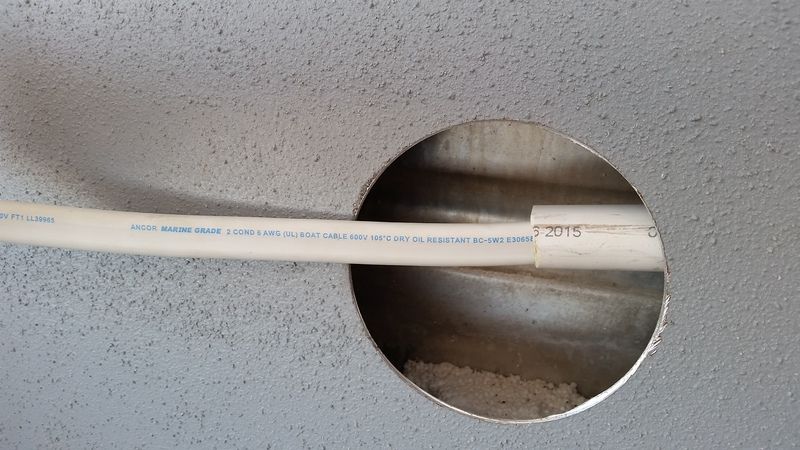

I ended up running some 2" PVC up front as a rigging tube for the starboard side. It was originally 1", but that quickly filled up.

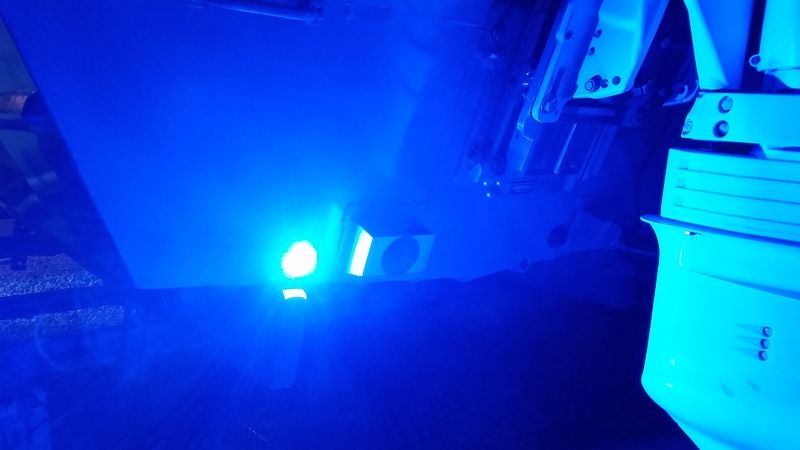

I ended up having to run two 2/0 battery cables, two 8 gauge wires for the jack plate, two 16 gauge wires for the fuel sender, and a 16/3 cable for the starboard nav light and spot light.

I also decided to relocate the primer bulb from above the rear deck, to below. This was just to make the rigging cleaner looking.

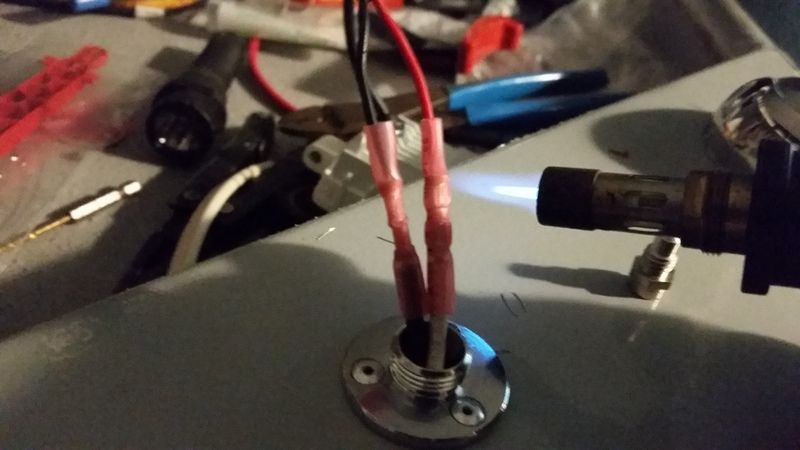

Because of the higher amperage draw from the jackplate, I decided to power it with the starting battery. This will leave the house battery to power the stereo, lights, bilge pump, livewell, and fishfinder. I had to modify the harness slightly to accommodate the longer run to the starting battery, and adding a bus bar was really helpful for connecting the 8 gauge wires, to the smaller 16 guage wires for the relay. I was disappointed in myself for mounting the bus bar so high. It didn't allow me enough room to make my ground wires look pretty...Oh well.

Back in November I replaced the GPS/fishfinder on my 23' Mako. I ended up getting a Lowrance Elite 7ti, and I love it. So...I'm getting rid of the Elite 7 unit I had previously on the boat, and decided it'd be much cheaper if I just buy the transducer, power cable, and mount for the Elite 7ti, then transfer the display from one boat to another. This works out perfectly, because I always remove the display and store it inside when I'm not using it. Here's a pic of the totalscan transducer mounted. It's a behemoth. On my Mako it doesn't looks so big, but on a Jon boat it looks HUGE.

Guages are also finished. I went with the Faria Dress White series. Got the system check tach, water pressure in the middle, and fuel on the bottom.

I ordered closed cell foam on eBay as advised by another member on here. I ended purchasing 10 pieces of 24" x 10" x 2". I almost fell over when I got it...I.coukdnt have cut it better if I measured. I took it out of the box and slid it right into place. No trimming or anything.

On a side note, we got a new boat in my area, so I drove down to check it out. It's a 33' 1000 Brunswick. It's strictly used for extended offshore patrol and special details. It's fully enclosed, with AC, and a generator, so the engines don't have to be operating the whole time. She carries 307 gallons of fuel!

Alright, that's it for now. Stay tuned!

Lots has been accomplished in the last couple weeks since I checked in. Once I got the engine hung, I start d working on the rigging. I bought new shorter shift cables from Amazon, and a shorter 12' steering cable. Turns out the steering cable was too short and I had to exchange it for a 13'.

The starting battery has been relocated up front for better weight distribution, and that called for an upgrade to the existing batter cables. I purchased about 17' of 2/0 battery cable for the run. I had a heck of a time fitting it through the rigging gromet, but I made it work.

I ended up running some 2" PVC up front as a rigging tube for the starboard side. It was originally 1", but that quickly filled up.

I ended up having to run two 2/0 battery cables, two 8 gauge wires for the jack plate, two 16 gauge wires for the fuel sender, and a 16/3 cable for the starboard nav light and spot light.

I also decided to relocate the primer bulb from above the rear deck, to below. This was just to make the rigging cleaner looking.

Because of the higher amperage draw from the jackplate, I decided to power it with the starting battery. This will leave the house battery to power the stereo, lights, bilge pump, livewell, and fishfinder. I had to modify the harness slightly to accommodate the longer run to the starting battery, and adding a bus bar was really helpful for connecting the 8 gauge wires, to the smaller 16 guage wires for the relay. I was disappointed in myself for mounting the bus bar so high. It didn't allow me enough room to make my ground wires look pretty...Oh well.

Back in November I replaced the GPS/fishfinder on my 23' Mako. I ended up getting a Lowrance Elite 7ti, and I love it. So...I'm getting rid of the Elite 7 unit I had previously on the boat, and decided it'd be much cheaper if I just buy the transducer, power cable, and mount for the Elite 7ti, then transfer the display from one boat to another. This works out perfectly, because I always remove the display and store it inside when I'm not using it. Here's a pic of the totalscan transducer mounted. It's a behemoth. On my Mako it doesn't looks so big, but on a Jon boat it looks HUGE.

Guages are also finished. I went with the Faria Dress White series. Got the system check tach, water pressure in the middle, and fuel on the bottom.

I ordered closed cell foam on eBay as advised by another member on here. I ended purchasing 10 pieces of 24" x 10" x 2". I almost fell over when I got it...I.coukdnt have cut it better if I measured. I took it out of the box and slid it right into place. No trimming or anything.

On a side note, we got a new boat in my area, so I drove down to check it out. It's a 33' 1000 Brunswick. It's strictly used for extended offshore patrol and special details. It's fully enclosed, with AC, and a generator, so the engines don't have to be operating the whole time. She carries 307 gallons of fuel!

Alright, that's it for now. Stay tuned!