mbweimar

Well-known member

Wow! It's been a while since I posted anything.

As of now, I've almost completely stripped the boat of paint. It's currently sitting upside down on the trailer. The leaning post is mounted with 1/4 x 20 aluminum rivnuts.

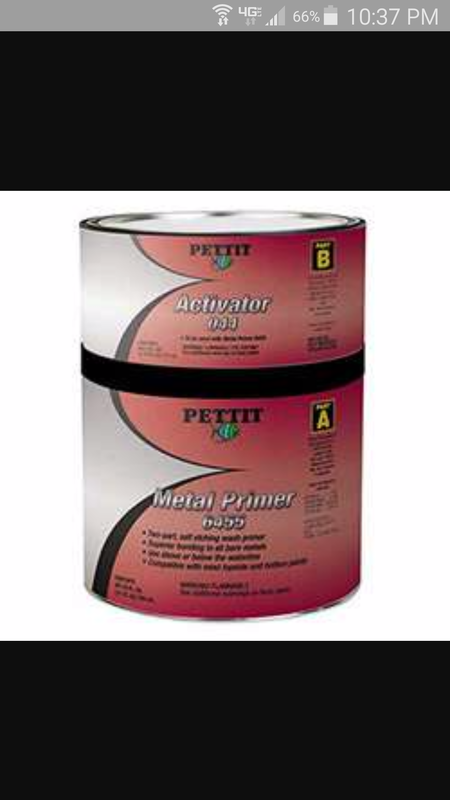

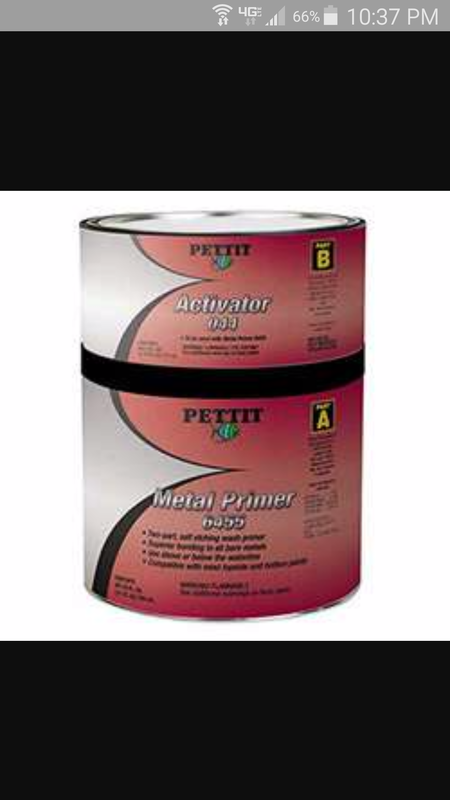

I'm getting closer to painting, and should be finished with paint in a few weeks. It seems the trend on here is using self etching rattle can primer, and duck boat paint. I've chosen to go with Pettit 6455/044 epoxy primer,

and Pettit 4700/4701 primer.

6455 is a self etching two part paint, and is applied as a semi transparent coat, then the 4700 is applied over it. I'm going for a gray look, so I probably won't put a top coat over the primer. On the decks, and floor I'll be going with Durabak in light gray. With any luck it will look like this. It's a thick, nonskid finish similar to truck bed liner. I'll be spraying everything with this bad boy. It's capable of spraying thick undercoating, and bed liner, as well as thinner paints!

With any luck it will look like this. It's a thick, nonskid finish similar to truck bed liner. I'll be spraying everything with this bad boy. It's capable of spraying thick undercoating, and bed liner, as well as thinner paints!

As of now, I've almost completely stripped the boat of paint. It's currently sitting upside down on the trailer. The leaning post is mounted with 1/4 x 20 aluminum rivnuts.

I'm getting closer to painting, and should be finished with paint in a few weeks. It seems the trend on here is using self etching rattle can primer, and duck boat paint. I've chosen to go with Pettit 6455/044 epoxy primer,

and Pettit 4700/4701 primer.

6455 is a self etching two part paint, and is applied as a semi transparent coat, then the 4700 is applied over it. I'm going for a gray look, so I probably won't put a top coat over the primer. On the decks, and floor I'll be going with Durabak in light gray.

With any luck it will look like this. It's a thick, nonskid finish similar to truck bed liner. I'll be spraying everything with this bad boy. It's capable of spraying thick undercoating, and bed liner, as well as thinner paints!

With any luck it will look like this. It's a thick, nonskid finish similar to truck bed liner. I'll be spraying everything with this bad boy. It's capable of spraying thick undercoating, and bed liner, as well as thinner paints!