Well I can now say I'M DONE! =D>

I finally got all the little things put back together and polished her up today. I was perfect weather for some completion pics so enjoy.

First off here is the new pumps and stern wiring I did a couple days ago. Took way to long to do but it's done right and looks good.

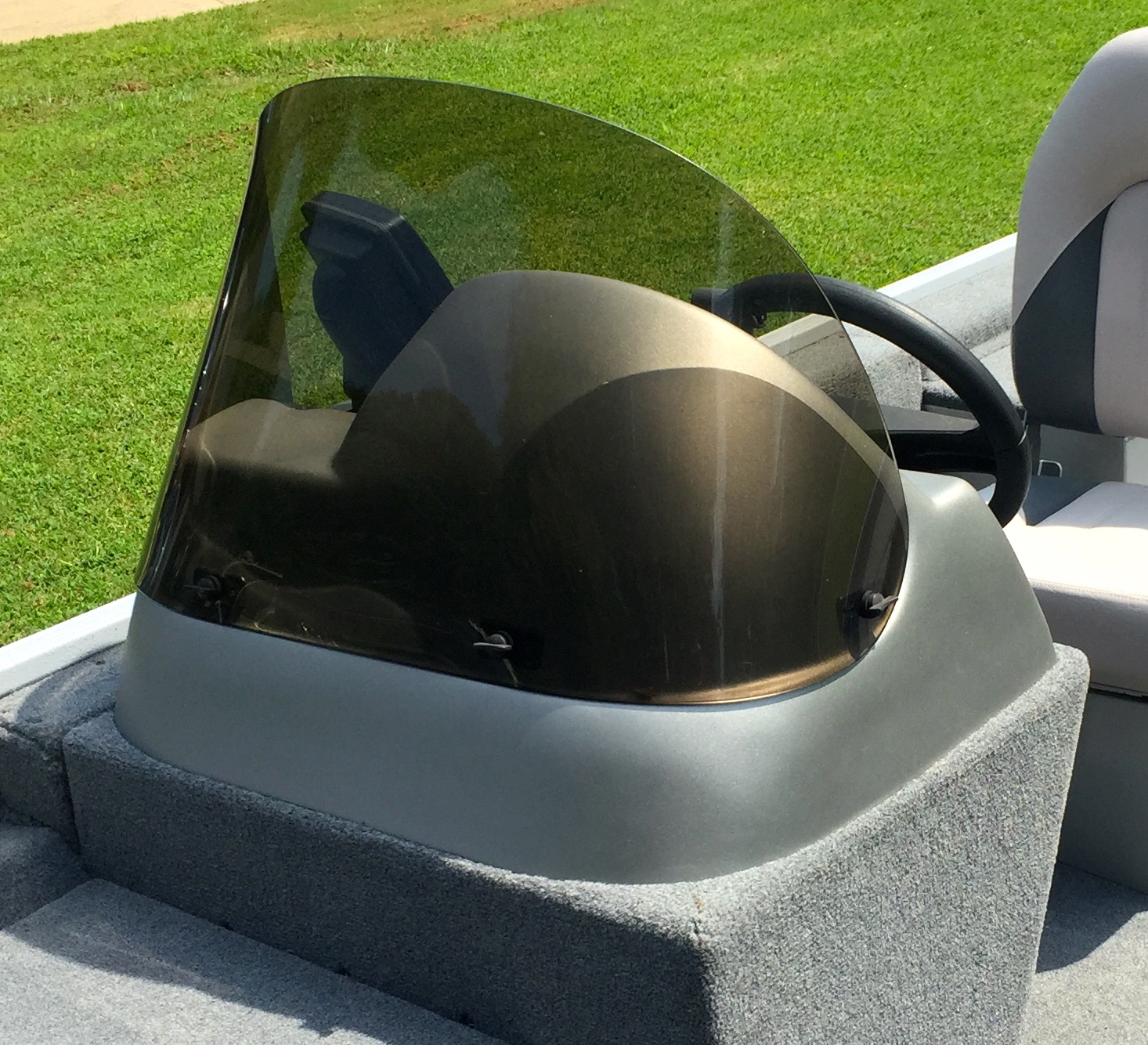

Remember this trashed council? New radio installed as well as some other things.

New seats, speakers etc. The new seat bases are so much better than the old big stationary units.

New trolling motor installed

Side beauty shot

The new and improved rod locker! Featuring fully carpeted inside and LED lights!

Look at all that carpet! I should have known better when I got it.

New guide-ons and some elbow grease on the fenders

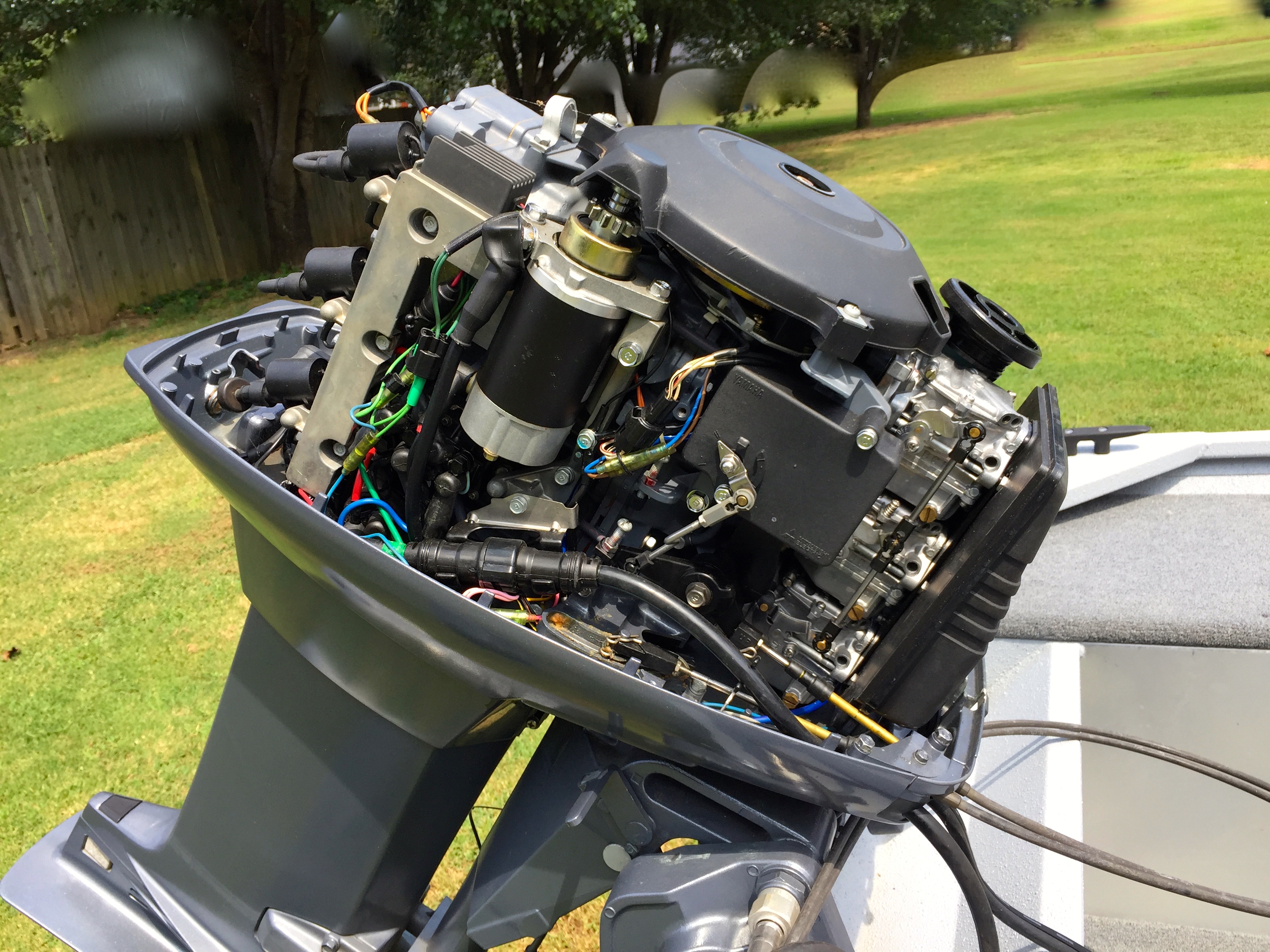

Inside look of the Yammy 50 (one of my all time favorite outboards) Yes I detailed the motor - Happy motor is a clean motor.

Well this one was a good boat to build, I know it had potential and solid bones to work off of. Took way longer than I wanted due to "life" but it's done, I wasn't rushed and took my time.

Here is the list of things replaced or repaired, keep in mind not everything is listed but it gives you a idea on the scope of the build.

1. New carpet - bigger job than you think if you want it too look the same or better than factory. Everything has to be removed and dissembled. I went with 20oz premium carpet so it was a upgrade from the 10oz it had new.

2. New LED lights inside

3. New Radio and speakers

4. New 55lb MinnKota Trolling motor

5. New complete Trolling motor power cable

6. New trolling motor connectors

7. New Bilge and Livewell pumps

8. New seat pedestal bases, pedestals and seats

9. Refurbished council

10. Wrapped panels on dash

11. Added main switch and LED switch

12. Wireloomed stern wiring and installed new connectors.

13. Painted assorted hardware (handles, doors etc)

14. Tuff Coated inner gunwales and top caps

15. New battery

16. Rewired trailer and installed new pigtail

17. New fuel line and connectors

18. Rebuilt carburetors and cleaned air box

19. Replaced water pump

20. Serviced lower unit

21. Installed new fuel lines in outboard

22. Replaced oil lines and adjusted oil pump to factory specs.

23. Verified timing and set idle to factory specs.

24. Replaced winch strap

25. Rebuilt wheel bearings

26. Rebuilt and carpeted side guide-ons

27. Greased steering and tilt zerks as well as brackets

I hope this gives someone some inspiration on rebuilding boats as I said before this is a great resource and I'm happy to contribute.

Last but not least the day I got it.

Before

After

Yes its FOR SALE!!