Quackrstackr

Well-known member

Hello folks, long time no see.

I have drug my feet for over 5 years now over doing something about my factory livewell. It's all aluminum construction, built onto the front of the console and is completely exposed. Saying that the water heats up in a hurry given the color of the boat is an understatement, even in colder months. I have grown tired of having to add ice to keep the fish alive or winding up with dead fish when I run off and forget it (like I did this past Sunday on a crappie outing). It doesn't have a livewell timer either (but it will soon).

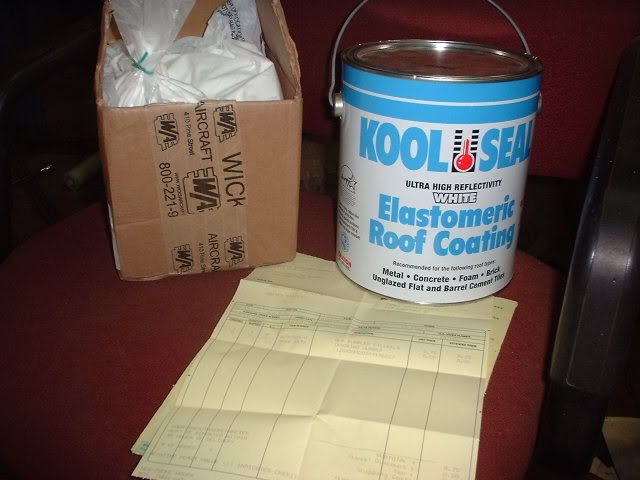

I have decided to put some insulation inside it and hopefully keep the water cooler for a much longer duration. It has to go inside because I don't want insulation stuck to the outside because the entire well is exposed. I found some info yesterday on a boating site about using the foil/bubble/foil insulation. It's taylor made to reflect radiant and convective heat absorbed through metal siding or roofing, so it should be ideal. It is also only 5/16" or so thick so it won't cut down on the livewell capacity very much. I am figuring to cut to fit the inner panels on all sides and then glue them in with silicone. The stuff is waterproof so as long as I seal the inner corner seams, I shouldn't have much of a problem with water getting behind it.

The only drawback that I can see is that I don't know how long it will stand up to fish pounding into it. Largemouth can get rather fiesty in there right after they are put in. I figure by glueing it in with silicone, I can peel panels out and replace them fairly easilly if I ever need to. Well, another drawback will be that it covers up my Tinboats decal that has been inside the lid for years now giving Jim some advertisement on social media sites... :lol:

Has anyone used this type of insulation in a livewell and if so, how well did it work?

https://www.lowes.com/pd_13357-56291-BP24025_0__?productId=3011904&Ntt=radiant+insulation&pl=1¤tURL=%3FNtt%3Dradiant%2Binsulation&facetInfo=

I have drug my feet for over 5 years now over doing something about my factory livewell. It's all aluminum construction, built onto the front of the console and is completely exposed. Saying that the water heats up in a hurry given the color of the boat is an understatement, even in colder months. I have grown tired of having to add ice to keep the fish alive or winding up with dead fish when I run off and forget it (like I did this past Sunday on a crappie outing). It doesn't have a livewell timer either (but it will soon).

I have decided to put some insulation inside it and hopefully keep the water cooler for a much longer duration. It has to go inside because I don't want insulation stuck to the outside because the entire well is exposed. I found some info yesterday on a boating site about using the foil/bubble/foil insulation. It's taylor made to reflect radiant and convective heat absorbed through metal siding or roofing, so it should be ideal. It is also only 5/16" or so thick so it won't cut down on the livewell capacity very much. I am figuring to cut to fit the inner panels on all sides and then glue them in with silicone. The stuff is waterproof so as long as I seal the inner corner seams, I shouldn't have much of a problem with water getting behind it.

The only drawback that I can see is that I don't know how long it will stand up to fish pounding into it. Largemouth can get rather fiesty in there right after they are put in. I figure by glueing it in with silicone, I can peel panels out and replace them fairly easilly if I ever need to. Well, another drawback will be that it covers up my Tinboats decal that has been inside the lid for years now giving Jim some advertisement on social media sites... :lol:

Has anyone used this type of insulation in a livewell and if so, how well did it work?

https://www.lowes.com/pd_13357-56291-BP24025_0__?productId=3011904&Ntt=radiant+insulation&pl=1¤tURL=%3FNtt%3Dradiant%2Binsulation&facetInfo=