Silverad04

Well-known member

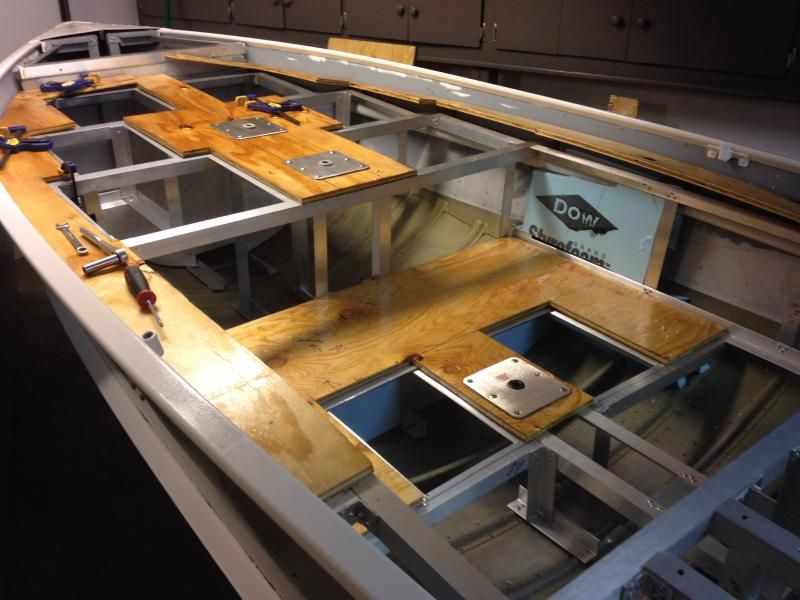

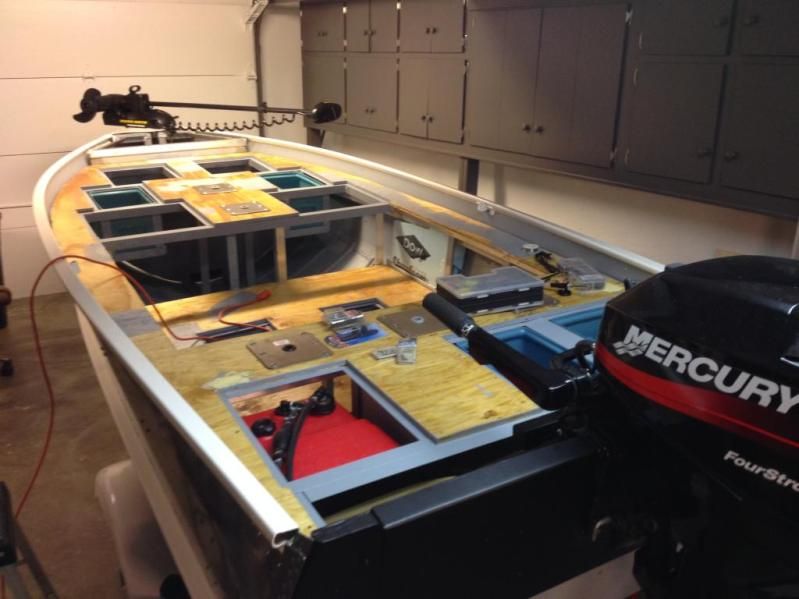

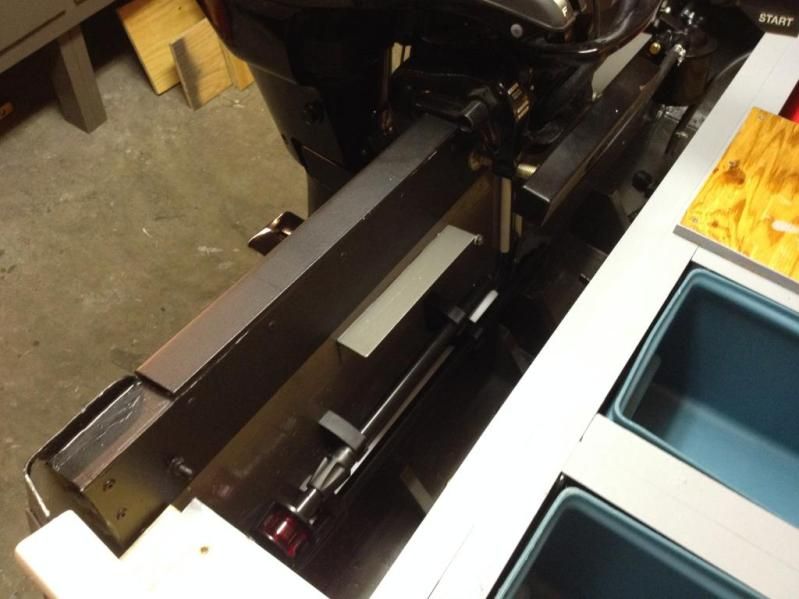

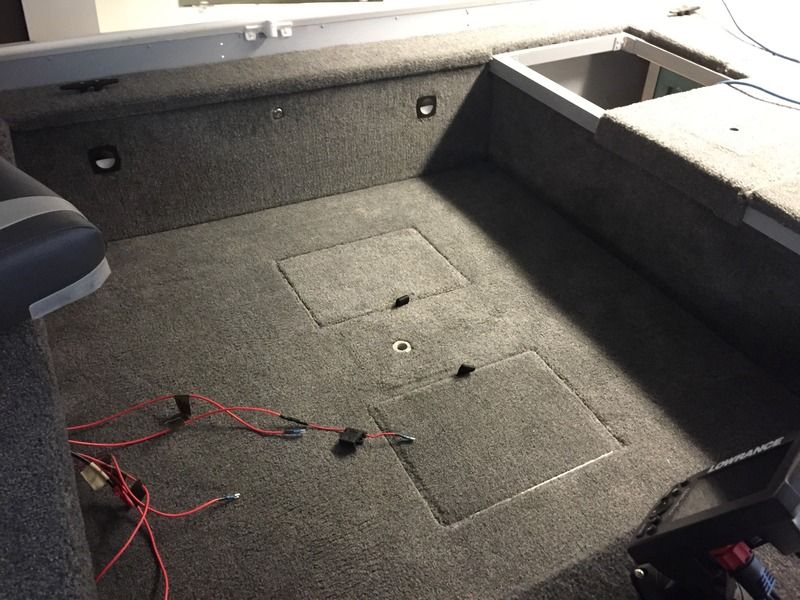

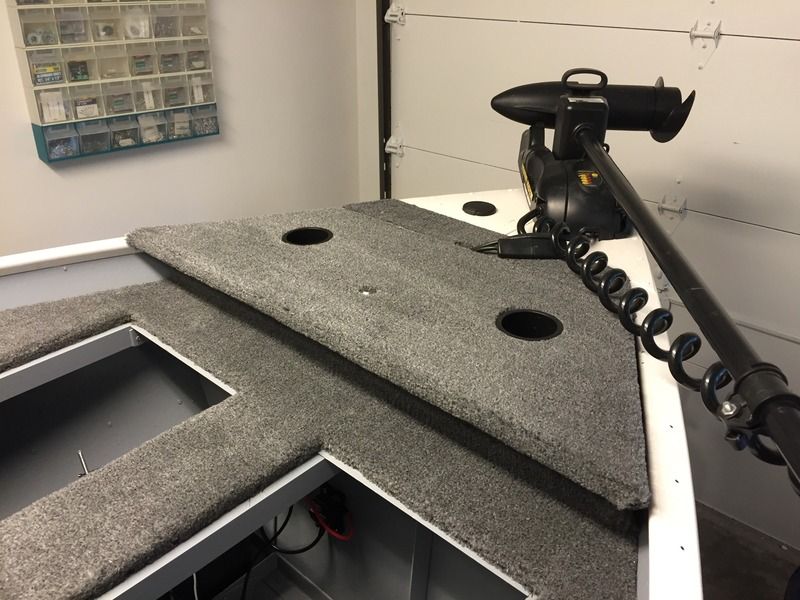

Well taking all of the paint off this hull turned out to be a pita. The stripper had a hard time getting all of the old paint off, I don't know if it was because it probably had lead in it or what, but it was on there. the first couple layers of paint came off quick, but the last layer was an aluminum color, and was hard as a rock. Here's the finished pictures of my Steelflex application. I tried to put the Steelflex on pretty thick, I used about 3/4 of a gallon. I think it turned out pretty good.