I've been lurking on here for awhile, joined to ask about some boats I found on CL a few weeks ago, and finally have my own boat to start modifying. I found a Monark 1648 flat bottom on CL from a member on here (I did not know he was a member until he sent me the link to his build). Anyway, I'm looking forward to this build, and need to get some things done before I go on vacation. I am heading on a vacation to MI in a month, and want to take the boat with me. I'm sure things will come up while fishing that I will want to change, modify, etc. from my original plan.

The boat came with two trolling motors, trailer, etc., and really was ready to fish, with the exception of deep cycle batteries. The boat already had a front deck, floor, and the transom was completely redone within the last 6 months and hadn't even been in the water. The deck and floor were made out of wood, and done correctly, but I just couldn't leave it alone. He gave me five, 4' X 8' X 1/8" sheets of composite sandwiched between aluminum to use.

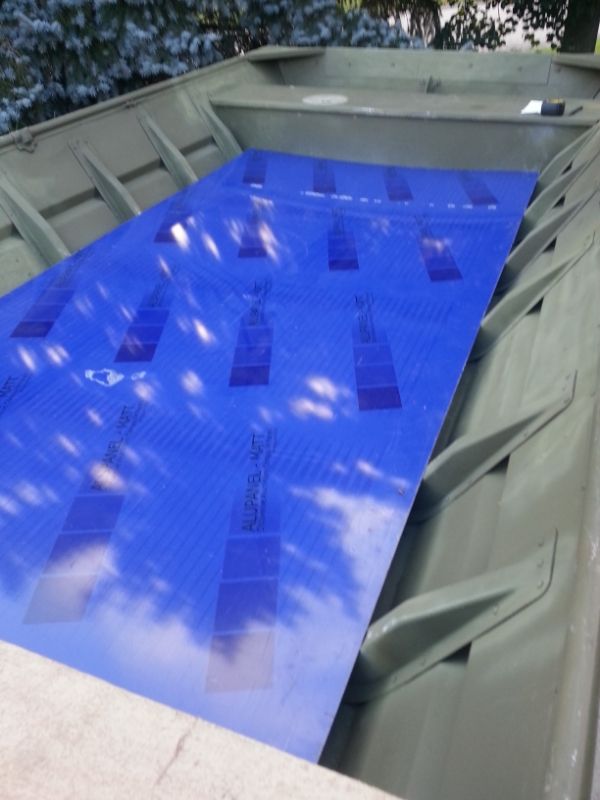

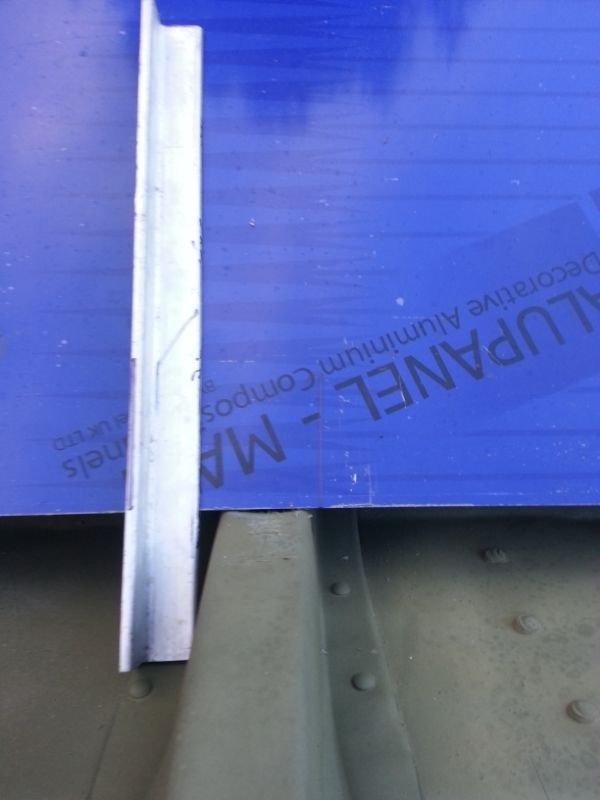

He gave me five, 4' X 8' X 1/8" sheets of composite sandwiched between aluminum to use.

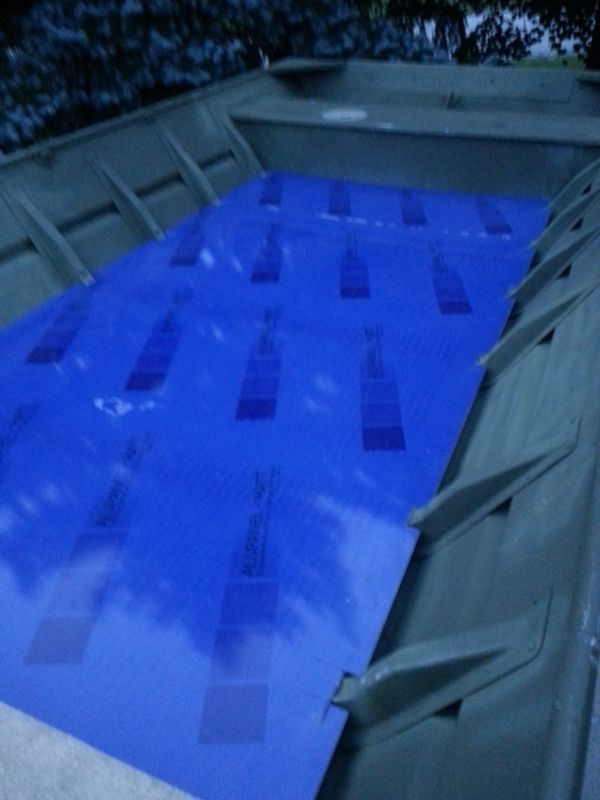

Here are some pics when I got it home:

As you can see, I could have just bought two batteries, and been on my way to the lake. Since I don't have an outboard yet, I wanted to lighten up the decking, floor, etc. so that my two trolling motors would be able to push me around a little faster. So, I decided to take out the wood to see what I was working with.

The front factory deck is pretty beat up, but it shouldn't matter, since I will be decking over it. I have thought about taking it out, re-bracing it with aluminum stock, but I've heard some horror stories about doing that. It would give me more storage room, but I don't want my boat to fall apart. Has anyone done this before and been successful?

I then performed a leak test. I filled it up with about 3" of water, let is sit overnight, and came out to find the boat does not leak! The previous owner told me that, but for my peace of mind, I wanted to know for sure. Actually, there was one little spot that leaked about the diameter of a grapefruit overnight. I'm not worried about that small of a leak.

After I drained all the water out, I started looking into the bench seating. I took the seat bases off to find that the foam was soaked, and holding water.

Well, that ain't going to fly, so I took out the middle bench first. I have never taken rivets out, but found it to be not so bad. Here is a pic showing the inside foam from the middle seat.

I then pressure washed the boat, and that's where I'm at now.

I plan on taking out the rear seat, to get the wet foam out. I'll put the rear seat back in, but not sure about the middle. I know there are two sides to that argument, but who knows?

Now, my tentative plans for the boat are to make it into a fly fishing river boat. I like the idea of a "flats" style boat, though this will never see salt. If you know fly fishing, your standing line always finds something to wrap around and get tangled, often when you are hooked up. Anyway, I'm thinking large front casting deck with a trolling motor and a rear casting deck for a second person. Not sure about the outboard, if I want tiller or console. I know console adds obstacles to get my line hung up on, but I like the idea of having a steering wheel. As for seats, my current thought is to add the bases under the decking, with the seats/posts in storage bins under the deck. That way, I won't trip over/get my line caught on the bases, but will have the option if I get tired, or if someone would rather sit. I plan on using aluminum stock/angle to frame up the decks, and the aluminum/composite sheets for the decking.

I really want to get at least the front deck and flooring in before my trip, so I can use the boat. So, I guess I will be ordering some aluminum tubing, rivets, and screws in the next few days and get started.

Sorry for the long-winded post, but I'm really excited to get started. Thanks for looking, and I appreciate all comments/suggestions/concerns, since this is my first boat. Tight loops, tight lines.

The boat came with two trolling motors, trailer, etc., and really was ready to fish, with the exception of deep cycle batteries. The boat already had a front deck, floor, and the transom was completely redone within the last 6 months and hadn't even been in the water. The deck and floor were made out of wood, and done correctly, but I just couldn't leave it alone.

Here are some pics when I got it home:

As you can see, I could have just bought two batteries, and been on my way to the lake. Since I don't have an outboard yet, I wanted to lighten up the decking, floor, etc. so that my two trolling motors would be able to push me around a little faster. So, I decided to take out the wood to see what I was working with.

The front factory deck is pretty beat up, but it shouldn't matter, since I will be decking over it. I have thought about taking it out, re-bracing it with aluminum stock, but I've heard some horror stories about doing that. It would give me more storage room, but I don't want my boat to fall apart. Has anyone done this before and been successful?

I then performed a leak test. I filled it up with about 3" of water, let is sit overnight, and came out to find the boat does not leak! The previous owner told me that, but for my peace of mind, I wanted to know for sure. Actually, there was one little spot that leaked about the diameter of a grapefruit overnight. I'm not worried about that small of a leak.

After I drained all the water out, I started looking into the bench seating. I took the seat bases off to find that the foam was soaked, and holding water.

Well, that ain't going to fly, so I took out the middle bench first. I have never taken rivets out, but found it to be not so bad. Here is a pic showing the inside foam from the middle seat.

I then pressure washed the boat, and that's where I'm at now.

I plan on taking out the rear seat, to get the wet foam out. I'll put the rear seat back in, but not sure about the middle. I know there are two sides to that argument, but who knows?

Now, my tentative plans for the boat are to make it into a fly fishing river boat. I like the idea of a "flats" style boat, though this will never see salt. If you know fly fishing, your standing line always finds something to wrap around and get tangled, often when you are hooked up. Anyway, I'm thinking large front casting deck with a trolling motor and a rear casting deck for a second person. Not sure about the outboard, if I want tiller or console. I know console adds obstacles to get my line hung up on, but I like the idea of having a steering wheel. As for seats, my current thought is to add the bases under the decking, with the seats/posts in storage bins under the deck. That way, I won't trip over/get my line caught on the bases, but will have the option if I get tired, or if someone would rather sit. I plan on using aluminum stock/angle to frame up the decks, and the aluminum/composite sheets for the decking.

I really want to get at least the front deck and flooring in before my trip, so I can use the boat. So, I guess I will be ordering some aluminum tubing, rivets, and screws in the next few days and get started.

Sorry for the long-winded post, but I'm really excited to get started. Thanks for looking, and I appreciate all comments/suggestions/concerns, since this is my first boat. Tight loops, tight lines.