ChitownBasser

Well-known member

- Joined

- Feb 7, 2012

- Messages

- 111

- Reaction score

- 0

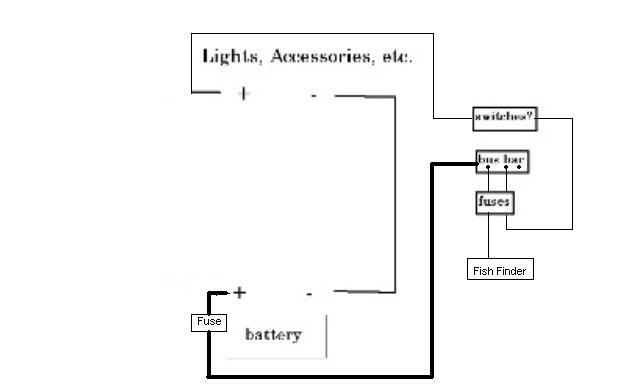

Hey fellas. My modifications to my 14' boat is going great thanks to this site. I've read a lot of posts and learned from most of them. I am almost to the point where I have to start thinking about electrical hook ups (lights, fishfinder, etc.).

From what I have read in this forum, I know the trolling motor should be hooked straight to the batter with an inline fuse. Right? Hook the fish finder straight to the battery, right? Which brings me to the lights. I want to use switches for the lights. I understand that I need fuses and a bus bar (not sure what it is). I have included a diagram that I need help completing. I am not how to rig it up. I am still going back and reading past posts to get an idea. btw I have a 12v Bass Pro Shops Deep Cycle Battery.

From what I have read in this forum, I know the trolling motor should be hooked straight to the batter with an inline fuse. Right? Hook the fish finder straight to the battery, right? Which brings me to the lights. I want to use switches for the lights. I understand that I need fuses and a bus bar (not sure what it is). I have included a diagram that I need help completing. I am not how to rig it up. I am still going back and reading past posts to get an idea. btw I have a 12v Bass Pro Shops Deep Cycle Battery.