You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2000 basstracker flats/duck hunting rebuild

- Thread starter Dirtmonkey

- Start date

Help Support TinBoats.net:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Dirtmonkey

Well-known member

- Joined

- Aug 20, 2017

- Messages

- 56

- Reaction score

- 0

I used t21 fusor and JB weld to fill the pits

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Dirtmonkey

Well-known member

- Joined

- Aug 20, 2017

- Messages

- 56

- Reaction score

- 0

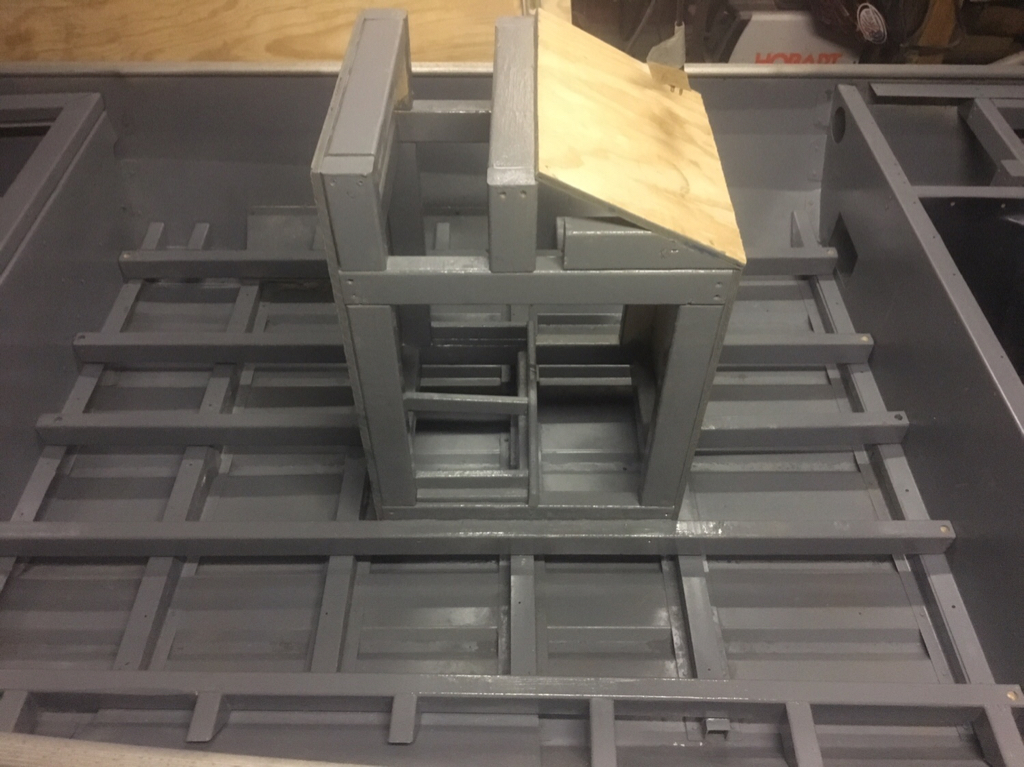

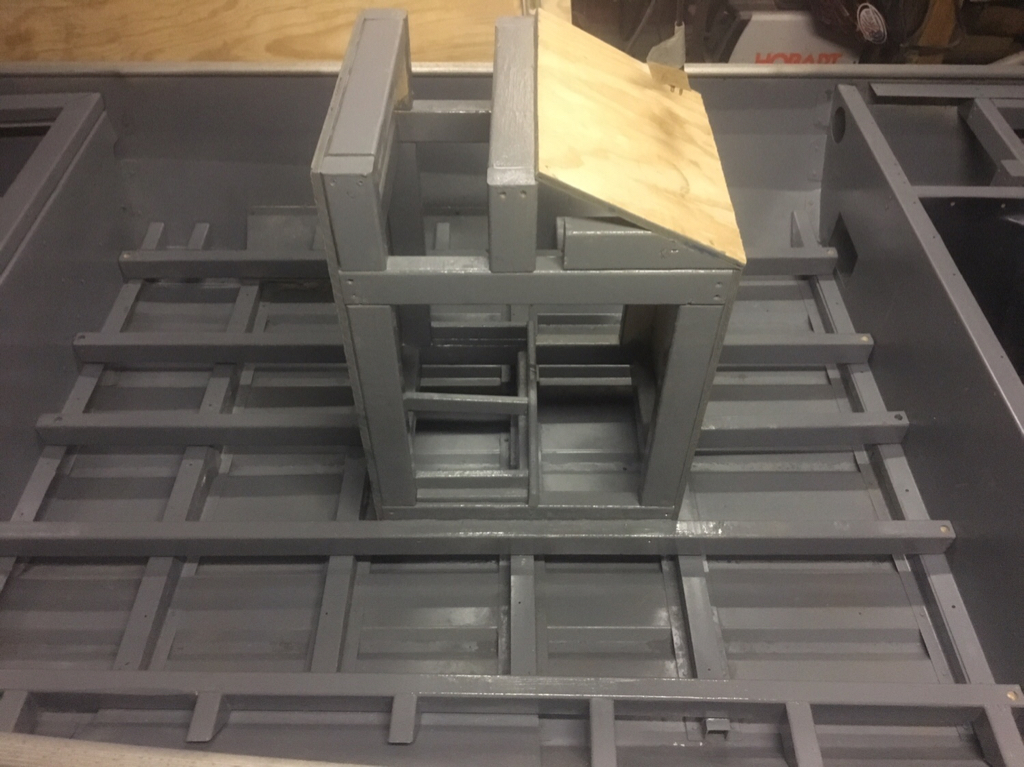

Well I've been getting a lot done on the boat over the last week. I got the front deck framed for all of the hatches and gas tank, got the rear deck framed out and got two tough boxes mounted as well as the livewell, painted the whole inside of the boat, got the center console mocked up and got the raised floor ready for paint, got my battery tray done and started laying out the console a little bit. I have a little bit more to do to the console before it can be prepped for paint, still have to finish framing the boxes for the front and then comes all of the wiring. I'm really starting to get anxious now that the majority of the framing is done

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Dirtmonkey

Well-known member

- Joined

- Aug 20, 2017

- Messages

- 56

- Reaction score

- 0

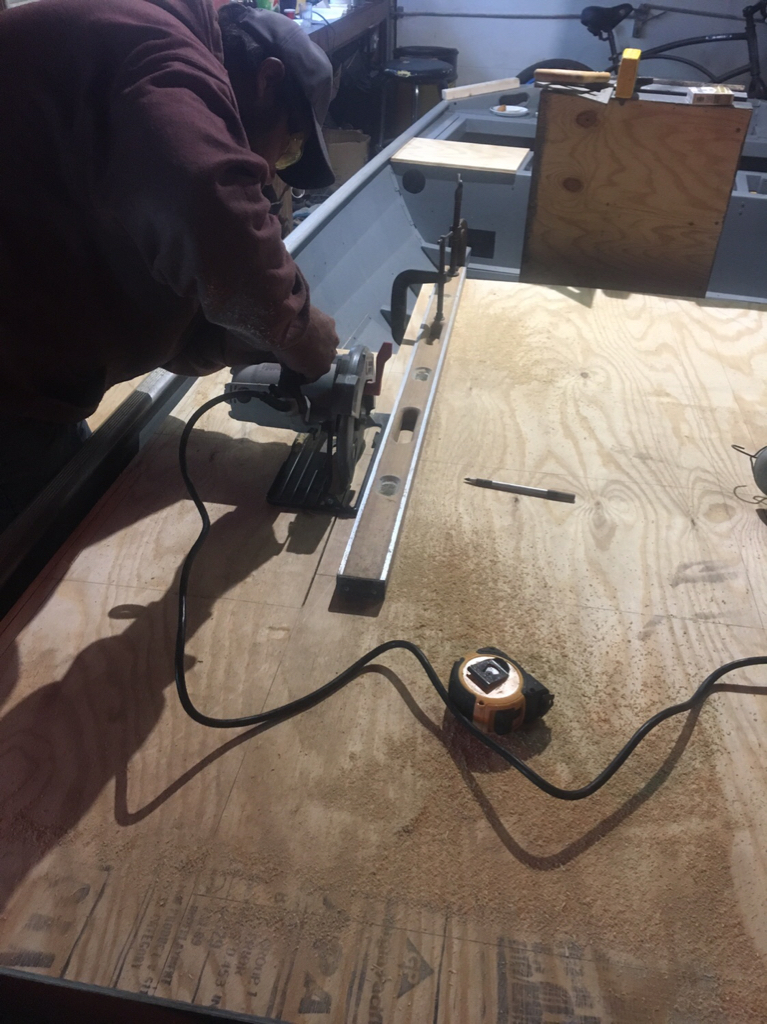

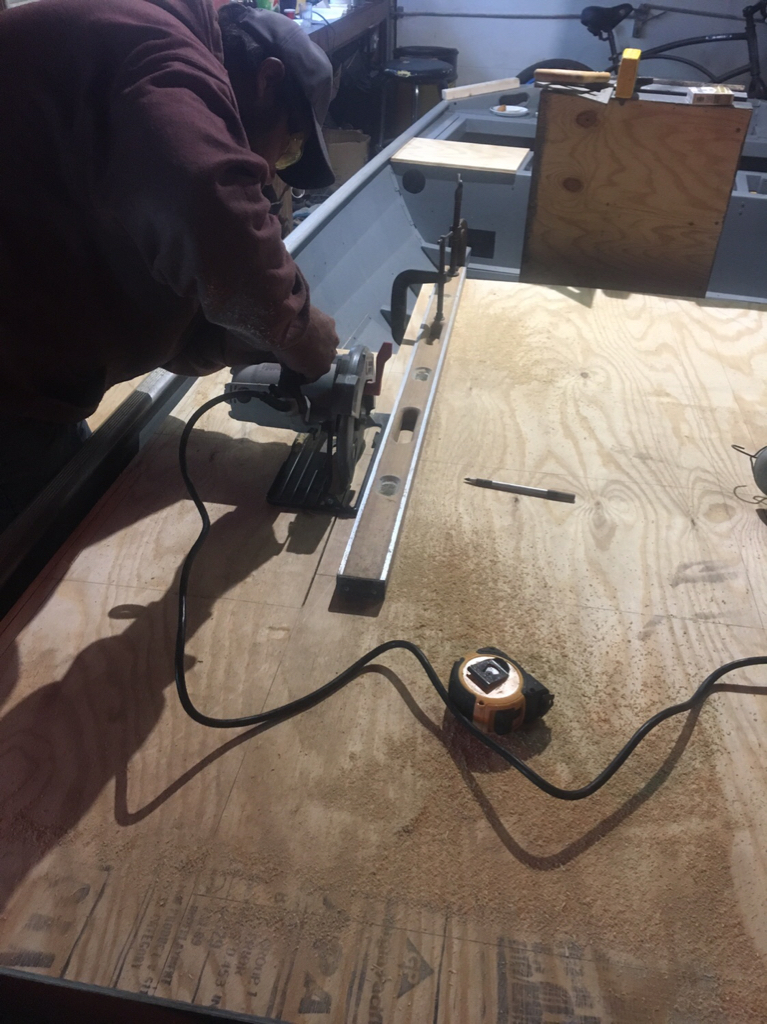

Got some more done tonight. All of the floor boards are painted, console is painted except the outside because I'll be spraying that after all of the body work. Got the whole back deck laid out on the wood and cut it out. It's definitely moving along now!

Had my little helper out with us tonight

Sent from my iPhone using Tapatalk

Had my little helper out with us tonight

Sent from my iPhone using Tapatalk

Dirtmonkey

Well-known member

- Joined

- Aug 20, 2017

- Messages

- 56

- Reaction score

- 0

SeaFaring said:Looking good! There’s a lot of progress in this post.

Sent from my iPhone using Tapatalk

Thank you, it was a really slow start but it's coming along!

Sent from my iPhone using Tapatalk

Dirtmonkey

Well-known member

- Joined

- Aug 20, 2017

- Messages

- 56

- Reaction score

- 0

Prowelder said:Looking good. You should check out my build I have a 97 with similar issues

Sent from my SM-G955U using Tapatalk

I was just scrolling thru Craigslist and saw your boat. small world because im in Virginia beach haha beautiful build man

Sent from my iPhone using Tapatalk

Prowelder

Well-known member

- Joined

- Jan 5, 2016

- Messages

- 426

- Reaction score

- 5

Thank manDirtmonkey said:Prowelder said:Looking good. You should check out my build I have a 97 with similar issues

Sent from my SM-G955U using Tapatalk

I was just scrolling thru Craigslist and saw your boat. small world because im in Virginia beach haha beautiful build man

Sent from my iPhone using Tapatalk

Sent from my SM-G955U using Tapatalk

Dirtmonkey

Well-known member

- Joined

- Aug 20, 2017

- Messages

- 56

- Reaction score

- 0

Prowelder said:If you need some metal work let me know

Sent from my SM-G955U using Tapatalk

I might cut the splash well out and replace the transom while I'm this far but I haven't committed to it yet. Do you have a tig machine or are you using a spool gun?

Sent from my iPhone using Tapatalk

Dirtmonkey

Well-known member

- Joined

- Aug 20, 2017

- Messages

- 56

- Reaction score

- 0

Prowelder said:Everything is tig Welded

Sent from my SM-G955U using Tapatalk

Well do you have an idea of what you'd want just to do the transom caps?

Sent from my iPhone using Tapatalk

Prowelder

Well-known member

- Joined

- Jan 5, 2016

- Messages

- 426

- Reaction score

- 5

I usually charge $25 an hour . 2 hr minimum. It would probably be less than 2 hours work if you get it all readyDirtmonkey said:Prowelder said:Everything is tig Welded

Sent from my SM-G955U using Tapatalk

Well do you have an idea of what you'd want just to do the transom caps?

Sent from my iPhone using Tapatalk

Sent from my SM-G955U using Tapatalk

RedHatRedNeck

Well-known member

[/quote]I usually charge $25 an hour . 2 hr minimum. [/quote]

**** where are you located? Might be worth the drive if you're not too far for some metal work if it could be worked into schedules.

**** where are you located? Might be worth the drive if you're not too far for some metal work if it could be worked into schedules.

Dirtmonkey

Well-known member

- Joined

- Aug 20, 2017

- Messages

- 56

- Reaction score

- 0

Cool man, I'll have some other work for you too. shoot me a text so I have your number, 332-2937Prowelder said:I usually charge $25 an hour . 2 hr minimum. It would probably be less than 2 hours work if you get it all readyDirtmonkey said:Prowelder said:Everything is tig Welded

Sent from my SM-G955U using Tapatalk

Well do you have an idea of what you'd want just to do the transom caps?

Sent from my iPhone using Tapatalk

Sent from my SM-G955U using Tapatalk

Sent from my iPhone using Tapatalk

Dirtmonkey

Well-known member

- Joined

- Aug 20, 2017

- Messages

- 56

- Reaction score

- 0

Well time to wake this thread up! I’ve taken a big break on this thing and now that the weather is warming up again I’ve gotten the itch to get this thing in the water. Quite a bit has gotten done since my last updates.

I finally got some man time in the garage last night and got a bunch of work done on it. Got the majority of the wiring, decks, hatches and lights mocked up. I can’t believe how much wire Ive stuffed into this little boat lol I still have to take everything out of the console and paint all of the wood on the inside. I’ve grown to be pretty OCD and wiring and especially in boats so here it is roughed in...

I also wanted to have a light in the console in case of an emergency but I didn’t want it to be one all of the time with the rest of the hatch lights. My solution was to run it’s one circuit with its own switch inside of the console. Keep in mind all of this wiring is just mocked up. I still have to pull it back out to paint the inside of the console.

It’s the little details to matter to me haha

So I found these lights at Walmart that are water resistant and they are made to go in the bed of a pickup. This whole time Ive been planning on doing L.E.D strip lights but these things were way to bright and convenient to pass up. Come to find out they fit absolutely perfect in the HDPE “tuffy” boxes I’m using as inserts in the back. These boxes are cheap and support over 200lbs on their own. That being said they are now removable if I ever need to access any wire or rigging.

I also took some time last night to sort through the factory harness and get rid of all of the factory non sense that has been replaced or isn’t needed. That’s a lot of useless wire. The second pic is what’s left of the harness and it’s mainly just for the engine and throttle assembly

I also made up some new power wire for the motor out of some 6/0. Even tho I wouldn’t have used it, the old wire wouldn’t reach anymore because I’ve moved the batteries from the back up to the console.

One more thing I got done last night is got the gas tank finally mounted in its new home in the front deck. Major pain in the butt getting everything lined up and fit correctly. The filler neck is now flushed into the front deck. Even tho there really isn’t anything to see, here is the filler neck in all of its glory! (Sorry the boat is a absolute mess)

Next on the agenda is getting the boxes built for the front deck, getting the lights mounted up there and start coating the decks with spar and non skid.

Sent from my iPhone using Tapatalk

I finally got some man time in the garage last night and got a bunch of work done on it. Got the majority of the wiring, decks, hatches and lights mocked up. I can’t believe how much wire Ive stuffed into this little boat lol I still have to take everything out of the console and paint all of the wood on the inside. I’ve grown to be pretty OCD and wiring and especially in boats so here it is roughed in...

I also wanted to have a light in the console in case of an emergency but I didn’t want it to be one all of the time with the rest of the hatch lights. My solution was to run it’s one circuit with its own switch inside of the console. Keep in mind all of this wiring is just mocked up. I still have to pull it back out to paint the inside of the console.

It’s the little details to matter to me haha

So I found these lights at Walmart that are water resistant and they are made to go in the bed of a pickup. This whole time Ive been planning on doing L.E.D strip lights but these things were way to bright and convenient to pass up. Come to find out they fit absolutely perfect in the HDPE “tuffy” boxes I’m using as inserts in the back. These boxes are cheap and support over 200lbs on their own. That being said they are now removable if I ever need to access any wire or rigging.

I also took some time last night to sort through the factory harness and get rid of all of the factory non sense that has been replaced or isn’t needed. That’s a lot of useless wire. The second pic is what’s left of the harness and it’s mainly just for the engine and throttle assembly

I also made up some new power wire for the motor out of some 6/0. Even tho I wouldn’t have used it, the old wire wouldn’t reach anymore because I’ve moved the batteries from the back up to the console.

One more thing I got done last night is got the gas tank finally mounted in its new home in the front deck. Major pain in the butt getting everything lined up and fit correctly. The filler neck is now flushed into the front deck. Even tho there really isn’t anything to see, here is the filler neck in all of its glory! (Sorry the boat is a absolute mess)

Next on the agenda is getting the boxes built for the front deck, getting the lights mounted up there and start coating the decks with spar and non skid.

Sent from my iPhone using Tapatalk

Similar threads

- Replies

- 13

- Views

- 2K

- Replies

- 112

- Views

- 11K

- Replies

- 33

- Views

- 6K

- Replies

- 2

- Views

- 1K