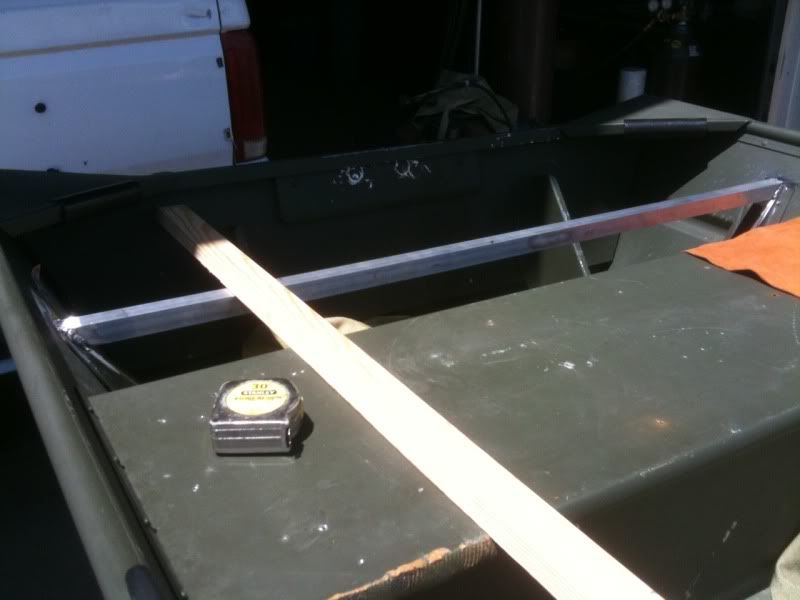

Poormans Boatright

Well-known member

Hey, Flatbotm, on what bends I used the JD2 Bender on I found that the aluminum wanted to dig into the follow bar and scrape the aluminum, to remedy this I had to apply a little grease on the backside of the tube to slide along the follow bar more freely. Maybe you wont have this problem. My problem was probably due to the fact my dies are tube and not pipe which have slightly different o.d.'s. For the most part I used a Greenlee bender which worked great. Your right a 3" radius is going to be tight, the bends on my rig are around 9" radius which I think made a smooth transition bend. Good luck, let us know how it comes out.